Introduction

A curtain wall is defined as thin, usually aluminum-framed wall, containing in-fills of glass, metal panels, or thin stone. The framing is attached to the building structure and does not carry the floor or roof loads of the building. The wind and gravity loads of the curtain wall are transferred to the building structure, typically at the floor line. Aluminum framed wall systems date back to the 1930's, and developed rapidly after World War II when the supply of aluminum became available for non-military use.

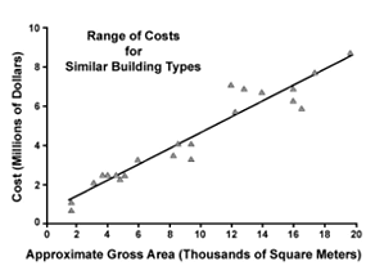

Curtain wall systems range from manufacturer's standard catalog systems to specialized custom walls. Custom walls become cost competitive with standard systems as the wall area increases. This section incorporates comments about standard and custom systems. It is recommended that consultants be hired with an expertise in custom curtain wall design for projects that incorporate these systems.

Description

The following are brief descriptions of commonly used curtain wall framing methods and components.

Curtain walls can be classified by their method of fabrication and installation into the following general categories: stick systems and unitized (also known as modular) systems. In the stick system, the curtain wall frame (mullions) and glass or opaque panels are installed and connected together piece by piece. In the unitized system, the curtain wall is composed of large units that are assembled and glazed in the factory, shipped to the site and erected on the building. Vertical and horizontal mullions of the modules mate together with the adjoining modules. Modules are generally constructed one story tall and one module wide but may incorporate multiple modules. Typical units are five to six feet wide.

Curtain walls can also be classified as water managed or pressure-equalized systems. See Moisture Protection below.

Both the unitized and stick-built systems are designed to be either interior or exterior glazed systems. Interior and exterior glazed systems offer different advantages and disadvantages. Interior glazed systems allow for glass or opaque panel installation into the curtain wall openings from the interior of the building. Details are not provided for interior glazed systems because air infiltration is a concern with interior glazed systems. Interior glazed systems are typically specified for applications with limited interior obstructions to allow adequate access to the interior of the curtain wall. For low rise construction with easy access to the building, outside glazing is typically specified. For high-rise construction interior glazing is sometimes used due to access and logistics of replacing glass from a swing stage.

In exterior glazed systems, glass and opaque panels are installed from the exterior of the curtain wall. Exterior glazed systems require swing stage or scaffolding access to the exterior of the curtain wall for repair or replacement. Some curtain wall systems can be glazed from either the interior or exterior.

Typical opaque panels include opacified spandrel glass, metal panels, thin stone, and other materials, such as terra cotta or FRP (fiber-reinforced plastic).

Vision glass is predominantly insulating glass and may have one or both lites laminated (see Glazing), usually fixed but sometimes glazed into operable window frames that are incorporated into the curtain wall framing.

Spandrel glass can be monolithic, laminated, or insulating glass. The spandrel glass can be made opaque through the use of opacifiers (film/paint or ceramic frit) applied on an unexposed surface or through "shadow box" construction, i.e., providing an enclosed space behind clear spandrel glass. Shadow box construction creates a perception of depth behind the spandrel glass that is sometimes desired.

Metal panels can take various forms including aluminum plate, stainless steel or other non-corrosive metal, thin composite panels consisting of two thin aluminum sheets sandwiching a thin plastic interlayer, or panels consisting of metal sheets bonded to rigid insulation, with or without an inner metal sheet to create a sandwich panel.

Thin stone panels are most commonly granite. White marble should not be used due to its susceptibility to deformation due to hysteresis (thin stone is not covered in this chapter).

The curtain wall often comprises one part of a building's wall system. Careful integration with adjacent elements such as other wall claddings, roofs, and base of wall details is required for a successful installation.

Fundamentals

System Types

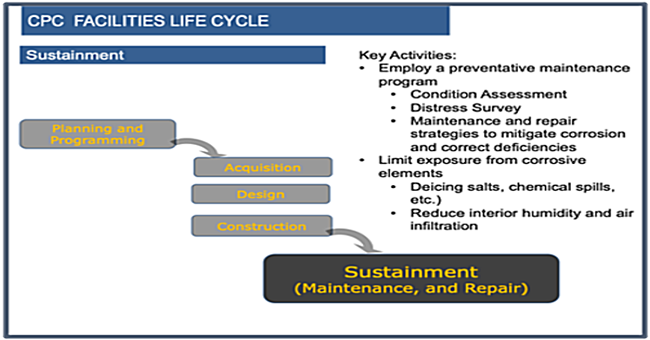

Face-sealed, water-managed and pressure-equalized rainscreen systems are the three systems that are available. Normally, pressure-equalized rain screen systems provide the highest levels of resistance to air and water infiltration, with water-managed systems the next most reliable.

Pressure-equalized rain screen systems function by blocking all of the forces that can drive water across a barrier. See the article on Moisture Protection for a complete explanation of how pressure-equalization resists water passage. As related to curtain wall systems, PE rain screen systems design the inside face of glass and the inside face of the glazing pocket and the interconnecting gasket or wet seal as an airtight barrier. The outside face of glass, exterior glazing materials and the outer exposed face of aluminum framing function as a rain screen, shedding water away. Between the exterior rain screen and the interior air barrier a pressure-equalization chamber is formed in the glazing pocket, which serves to reduce water penetration by eliminating (equalizing) the pressure difference across the rain screen that tends to force water into the system. Minor amounts of water that may penetrate the system are weeped harmlessly to the exterior.

Water-managed systems appear similar at first glance, incorporating drains and weeps from the glazing pocket, but no effort is made to create an air barrier or "zone-glaze" each glass or spandrel unit, and therefore a larger amount of water is forced into the system and must be weeped away. Also, since no air barrier exists, the pressure differential between the glazing pocket and the interior may be strong enough to force water vertically higher than interior gaskets, resulting in leaks. Weep holes in a water-managed system function largely to drain water that enters the glazing pocket while weep holes in a pressure-equalized system function primarily as vents to allow air movement between the exterior and glazing pocket. Weeping of water is only a secondary function. Note that the easiest way to recognize a pressure-equalized rain screen system is yo note that the that glazing pocket around each individual unit of glass is isolated air tight from adjacent units, most obviously with plugs or seals at the gaps between screw splines at mullion intersections. Detailing of spandrels, shadow boxes and interface with adjacent construction must maintain the continuity of the air barrier and rainscreen to function properly with a pressure-equalized rainscreen curtain wall framing system.

Some aluminum curtain wall systems are still designed as face-sealed barrier walls. They depend on continuous and perfect seals between the glass units and the frame and between all frame members to perform. The long-term reliability of such seals is extremely suspect and such systems should be avoided.

Thermal Performance (Conduction, Solar Radiation, Thermal Break, Comfort)

Overall curtain wall thermal performance is a function of the glazing infill panel, the frame, construction behind opaque (spandrel and column cover) areas, and the perimeter details.

Curtain wall frame conductance is a function of the frame material, geometry and fabrication (e.g. thermal break).

Aluminum has a very high thermal conductivity. It is common practice to incorporate thermal breaks of low conductivity materials, traditionally PVC, Neoprene rubber, polyurethane and more recently polyester-reinforced nylon, for improved thermal performance. Some "poured and debridged" polyurethane thermal breaks shrink and stress forms in the thermal break when the exterior aluminum moves differently from the interior aluminum due to temperature differences. Back-up mechanical attachment of the two halves of the frame is recommended (e.g. skip debridging or "t-in-a box"). A true thermal break is ¼" thick minimum and can be up to 1" or more, with the polyester reinforced nylon variety. Some curtain wall systems incorporate separators that are less than ¼", making them "thermally improved". The deeper thermal breaks can improve thermal performance and condensation resistance of the system.

Some curtain wall systems utilize "pressure bars" (also referred to as "pressure plates") that are fastened to the outside of the mullions to retain the glass. These systems frequently include gaskets that are placed between the pressure bar and mullions and function as thermal breaks and help with acoustic isolation. These systems require special care in design and construction to ensure continuity of the gaskets at horizontal and vertical transitions. Gaskets are also used to cushion the glass on the interior and exterior faces of the glass. The problem with gaskets is that they tend to be stretched during installation and will shrink back to their original length in a short time; they will also shrink with age and exposure to ultraviolet radiation. There is usually a gap in the gasket at the corners after shrinkage occurs. With a properly designed system the water that enters the system at the gasket corners will weep out through the snap cover weep holes. To mitigate shrinkage of gaskets back from the corners the use of vulcanized corners and diagonally cut splices are recommended.

Thermal performance of opaque areas of the curtain wall is a function of insulation and air/vapor barriers. Due to the lack of interior air adjacent to opaque curtain wall areas, these areas are subject to wide swings in temperature and humidity and require careful detailing of insulation and air/vapor barriers to minimize condensation. Some curtain wall systems include condensation drainage provisions, such as condensate gutters, that are intended to collect and weep condensate from spandrel areas to the exterior; such condensate gutters and weeps are a violation of the air barrier of the curtain wall unless they are outboard of the backpan. See discussion of back pans below.

At the curtain wall perimeter, maintaining continuity of the air barrier reduces airflows around the curtain wall. Integration of perimeter flashings helps ensure watertight performance of the curtain wall and its connection to adjacent wall elements. Proper placement of insulation at the curtain wall perimeter reduces energy loss and potential condensation issues. Insulating the mullions in a spandrel area may lead to excessive condensation in cold climates unless it can also be assured that humid air from the interior will never come in contact with the mullions. The spandrel area is typically not heated, thus the interior environment does not warm the mullions and offset the migration of the cold temperatures deep into the wall. In the vision area the interior heat helps to mitigate the cold and prevents condensation. For this reason, do not insulate between the interior portion of mullions and adjacent wall construction either.

Moisture Protection (Water Penetration, Condensation Resistance)

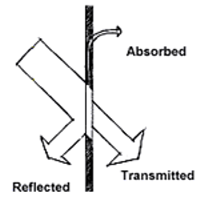

Water penetration resistance is a function of glazing details (see Glazing), frame construction and drainage details, weatherstripping and frame gaskets, interior sealants (for operable windows, see Windows), and perimeter flashings and seals. Water can enter the exterior wall system by means of five different forces: gravity, kinetic energy, air pressure difference, surface tension, and capillary action. To mitigate water infiltration, all of these forces must be accounted for in the system design.

Unlike discontinuous windows, which are smaller units and can rely to a high degree on sill flashings to capture frame corner leakage, curtain walls cover large expanses of wall without sill flashings at each glazed opening. Water penetration of curtain wall frame corners is likely to leak to the interior and/or onto insulating glass below. Watertight frame corner construction and good glazing pocket drainage are critical for reliable water penetration resistance.

Key visual features of curtain walls are glazing appearance (see Glazing) and sightlines. Sightlines are defined as the visual profile of the vertical and horizontal mullions. The sightlines are a function of both the width and depth of the curtain wall frame. Lateral load resistance requirements (wind loads, spans) generally dictate frame depth. Where narrow sightlines are desired, steel stiffeners inserted into the hollow frame of aluminum extrusions can help reduce frame depth.

The acoustic performance of curtain walls is primarily a function of the glazing and internal seals to stop air leakage (covered elsewhere). The sound attenuation capability of curtain walls can be improved by installing sound attenuating infill and by making construction as airtight as possible. Incorporating different thicknesses of glass in an insulated glass unit will also help to mitigate exterior noise. This can be accomplished by increasing the thickness of one of the lites of glass or by incorporating a laminated layer of glass with a noise-reducing interlayer, typically a polyvinyl butyral or PVB.

Back Pans

Back pans are metal sheets, usually aluminum or galvanized steel, that are attached and sealed to the curtain wall framing around the perimeter behind opaque areas of a curtain wall. In cold climates insulation should be installed between the back pan and the exterior cladding in order to maintain the dew point outboard of the back pan so that the back pan acts as an air and vapor barrier. Back pans provide a second line of defense against water infiltration for areas of the curtain wall that are not visible from the interior and are difficult to access. Water infiltration in opaque areas can continue for extended periods of time causing significant damage before being detected. Back pans also are to be preferred over foil vapor retarders in high performance and humidified buildings as convection currents short-circuiting the insulation can cause condensation, wetting and ultimately failure of these spandrel areas.

Shadow Boxes

Shadow box construction creates the appearance of depth behind a transparent lite of glass by incorporating a metal sheet into the curtain wall behind the lite. The metal sheet should be at least two inches behind the glass and may be painted or formed to create a texture, but reflective surfaces add the most visual depth to the wall. Insulation should also be installed behind the shadow box if interior finishes prevent room air from contacting this area. The system should be designed to collect any condensation that may collect on the exterior side of the metal sheet and drain it back to the exterior. Shadow boxes present a variety of challenges related to venting the cavity behind the glass, that can allow dirt on surfaces difficult to clean, or sealing the cavity and risking excessive heat build-up. Either way, the cavity may be at temperatures significantly above or below interior conditions with only thermally conductive aluminum between them. This can lead to condensation or surfaces so hot they can burn. Careful detailing can provide a method to thermally isolate the cavity from the interior. An interior back pan behind the insulation is desirable as well, to avoid condensation on the metal shadow box from the interior.

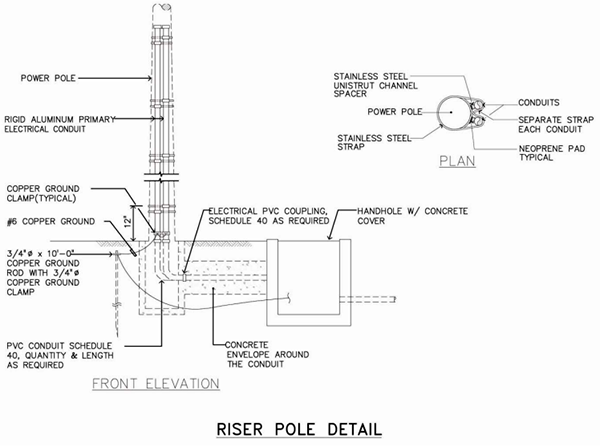

Support of Curtain Walls

Curtain wall systems must transfer back to floor structure or intermediate framing both their own dead load plus any live loads, which consist primarily of positive and negative wind loads but might also include a snow load applied to large horizontal areas, seismic loads, maintenance loads and others. Unfortunately, the curtain wall will likely demonstrate movement caused by thermal changes and wind significantly different than movement of the building structure. Therefore the connections to anchor the curtain wall must be designed to allow differential movement while resisting the loads applied.

In stick-framed aluminum curtain wall, vertical mullions commonly run past two floors, with a combined gravity/lateral anchor at one floor and a lateral anchor only at the other. The splice between the vertical mullions will also be designed to allow vertical movement while providing lateral resistance. In large areas of stick framed curtain wall, a split vertical mullion will be introduced periodically to allow thermal movement. Note that this movement slightly distorts the anchors at the vertical mullions. Individual units of glass must accommodate the movement of the surrounding aluminum frame by sliding along glazing gaskets, distorting the gaskets or a combination of both. The movement of the glass within the frame and the movement forced in the anchors tend to induce additional stresses into a stick framed system.

Unitized curtain wall systems accommodate the differential movement between the structure and the thermal movement of the frame at the joints between each curtain wall unit. Because these units are frequently custom designed, the amount of movement to be accommodated can be carefully engineered into the system. Anchoring of unitized curtain wall typically consists of a proprietary assembly with three-way dimensional adjustability. The anchors occur at each pair of vertical mullions along the edge of slab or spandrel beam. Frequently, unitized systems span from a horizontal stack joint located at approximately desk height up to the anchor at the floor line above and then cantilevering past the floor to the next horizontal stack joint. The stack joint is designed to resist lateral loads while the two floor anchors resist gravity and lateral loads. One of the two floor anchors will allow movement in plane with the unitized system.

Fire Safety

Fire safing and smoke seal at gaps between the floor slab-edge and the back of the curtain wall are essential to compartmentalize between floors and slow down the passage of fire and combustion gases between floors. A substantial ½" thick minimum poured smoke-seal is required to separate air return and supply plenums from each other, and for infection control in hospitals. Laboratory-tested fire rated assemblies may be required in unsprinklered buildings by some codes as Perimeter Fire Containment Systems when the floor assemblies are required to be fire-resistance rated. The ratings of the Perimeter Fire Containment System must be equal to or greater than the floor rating. These systems provide confidence that the materials used for perimeter containment remain in place for the specified duration of the required rating in a fire event.

Fireman knock-out glazing panels are often required for venting and emergency access from the exterior. Knock-out panels are generally fully tempered glass to allow full fracturing of the panel into small pieces and relatively safe removal from the opening. Knock-out panels are identified by a non-removable reflective dot (typically two inches in diameter) located in the lower corner of the glass and visible from the ground by the fire department.

Falling Ice and Snow

Buildings in cold climates have struggled throughout the ages with ice and snow formations that slide, fall, or get windblown from their roofs, ledges, and window sills, causing harm to people and damage to property below. Refer to the Resource Page on Considerations for Building Design in Cold Climates.

The curtain wall should be designed for accessibility for maintenance. Low-rise buildings can generally be accessed from the ground using equipment with articulated arms. For high rise construction the building should be designed for swing stage access for window cleaning, general maintenance, and repair work, like glass replacement. Davits and fall arrest safety tieback anchors should be provided on the roof and stabilization tie-offs provided on the face of the wall to comply with OSHA standards CFR 1910.66, CFR 1910.28 and ANSI/IWCA I-14.1 "Window Cleaning Safety Standard".

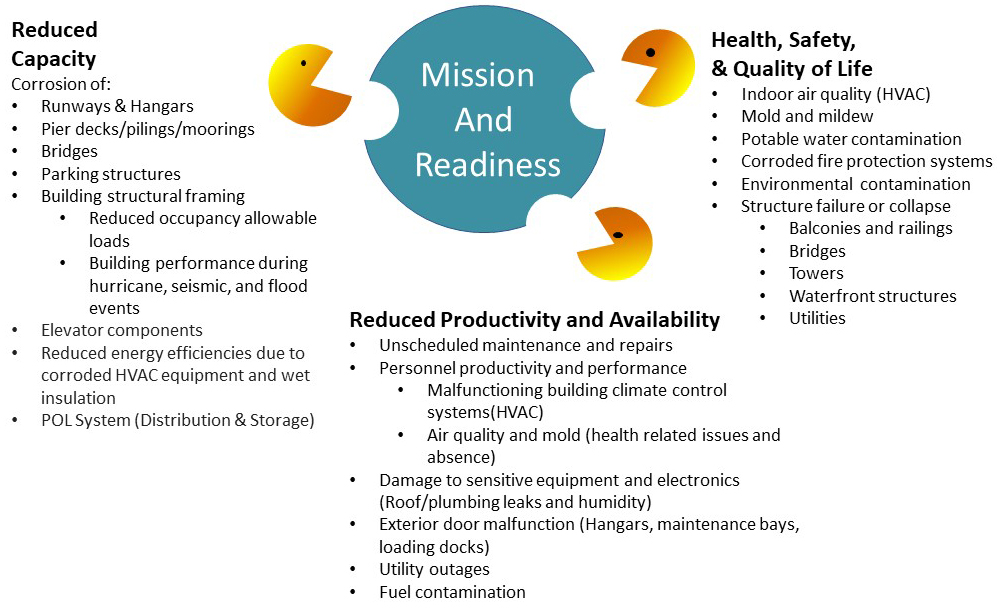

Curtain wall leakage, both air and water, can contribute to IAQ problems by supplying liquid water and condensation moisture for mold growth. This leakage can often remain concealed within the wall system and not become evident until concealed wall components experience significant deterioration and mold growth, requiring costly repairs.

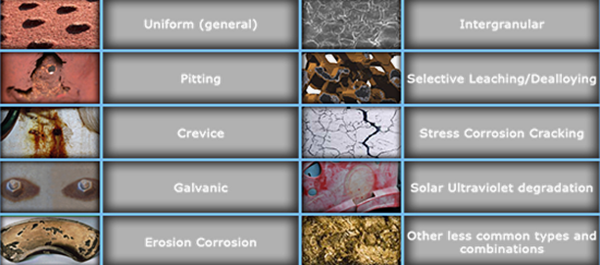

Common curtain wall durability problems include the following:

Glazing failures (see Glazing). Glazing problems specific to curtain wall construction include visual obstruction from condensation or dirt, damage to opacifier films from material degradation, condensation and/or heat build-up, and IGU issues/laminated glass issues.

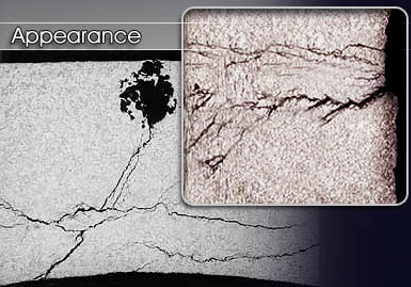

Failure of internal gaskets and sealants from curtain wall movements (thermal, structural), prolonged exposure to water (good drainage features reduce this risk), heat/sun/UV degradation (age). Repairs (if feasible) require significant disassembly of curtain wall. If restoration of internal seals is not physically possible or not economically feasible, installation of exterior surface wet sealing at all glazing and frame joints is often performed.

Failure of exposed gaskets and sealants, including perimeter sealants, from curtain wall movements (thermal, structural), environmental degradation. Repairs require exterior access.

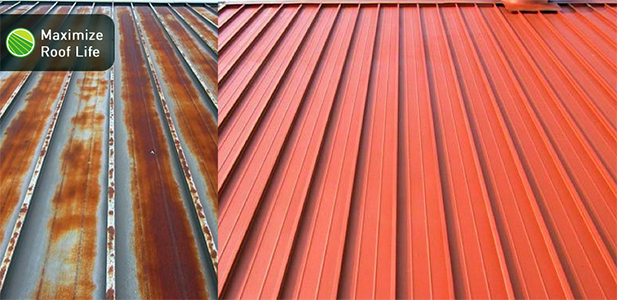

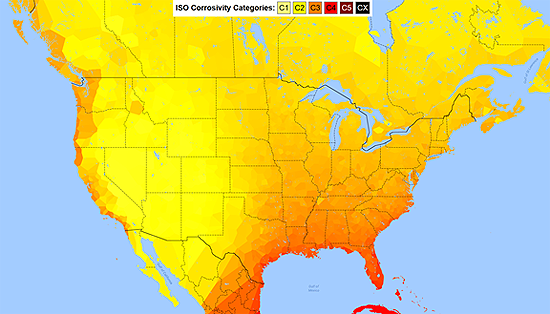

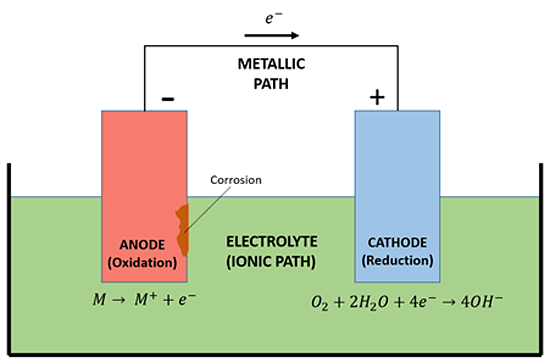

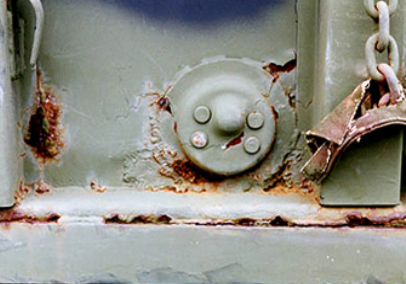

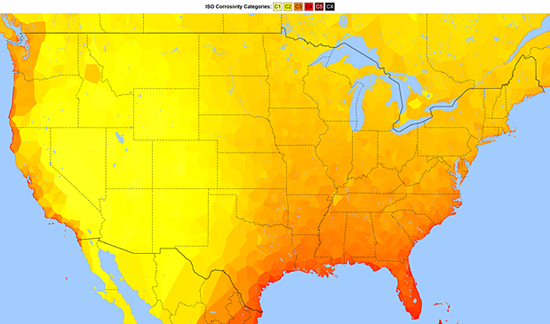

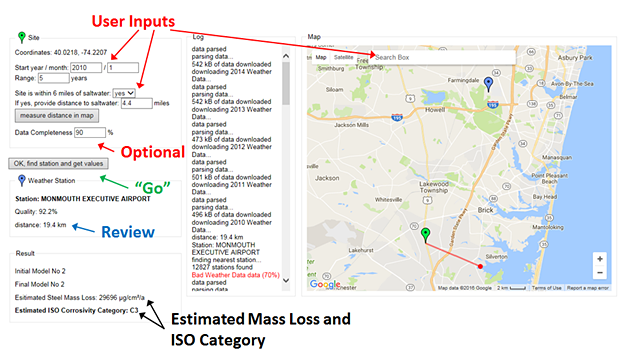

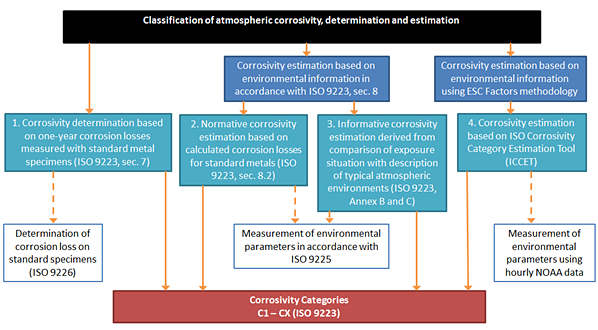

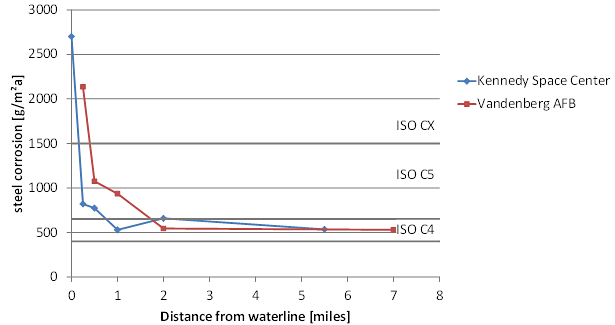

Aluminum frames are inherently corrosion resistant in many environments if anodized and properly sealed or painted with baked-on fluoropolymer paint. Aluminum frames are subject to deterioration of the coating and corrosion of aluminum in severe (industrial, coastal) environments and galvanic corrosion from contact with dissimilar metals. Frame corner seals constructed using sealant are prone to debonding from prolonged contact with moisture and from thermal, structural, and transportation movements.

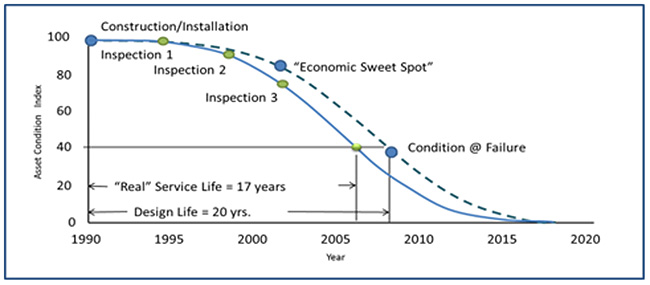

Curtain walls and perimeter sealants require maintenance to maximize the service life of the curtain walls. Perimeter sealants, properly designed and installed, have a typical service life of 10 to 15 years although breaches are likely from day one. Removal and replacement of perimeter sealants requires meticulous surface preparation and proper detailing.

Aluminum frames are generally painted or anodized. Factory applied fluoropolymer thermoset coatings have good resistance to environmental degradation and require only periodic cleaning. Recoating with an air-dry fluoropolymer coating is possible but requires special surface preparation and is not as durable as the baked-on original coating.

Anodized aluminum frames cannot be "re-anodized" in place, but can be cleaned and protected by proprietary clear coatings to improve appearance and durability.

Exposed glazing seals and gaskets require inspection and maintenance to minimize water penetration, limit exposure of frame seals, and protect insulating glass seals from wetting.

The best strategy for sustainability of curtain walls is to employ good design practices to ensure the durability (maximum service life) of the installation and to use systems that have a good thermal break and high R-value (values as high as R-7 are possible with triple-glazed systems). Also, the use of low-e and spectrally selective glass coatings can significantly reduce energy loads and improve comfort close to the wall.

Aluminum and steel frames are typically recycled at the end of their service life. Salvage and demolition contractors generally require a minimum of 1,000 sq ft or more of window/curtain wall to make material recycling economical (smaller amounts are generally disposed as general trash). Recycling is less economical if the aluminum is contaminated with sealants, fractured glazing, etc., as salvage companies pay considerably less for the material. There is a limited market for salvaged steel and wood frames.

Applications

Establish System Track Record

Select a curtain wall with a demonstrated track record in similar applications and exposures. Verifying track records may require significant research by the designer. ASTM E1825 provides guidance.

Review laboratory test results of systems or similar custom systems for air, water, and structural resistance, heat transmission, condensation resistance, sound transmission, and operability. Verify that tests pertain to the system under consideration and not a version of the system with the same product name but of different construction.

Curtain wall design should start with the assumption that external glazing seals, perimeter sealant joints and curtain wall sills will leak. The following summarizes recommended features:

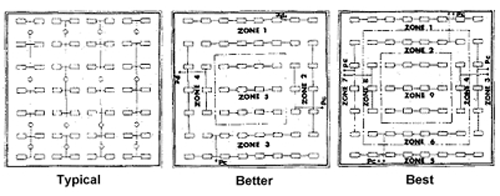

- Select frames with wept glazing and pocket sills sloped to the exterior to collect water that penetrates the glazing and drain it to the exterior. Do not use vertical mullions as drain conductors. Each glazing pocket should be fully isolated from adjacent glazing pockets. Provide a sill flashing with end dams and with an upturned back leg turned up into the glazing pocket at the base of the curtain wall to collect and drain curtain wall sill leakage; provide jamb flashings to direct perimeter leakage down to the sill flashing.

- Key frame drainage features include slope to the exterior at surfaces that collect water (slope top of exposed horizontal mullion surfaces, slope at flashings), large (3/8 inch diameter or a slot 5/16" x 3/8" minimum) weep holes closely spaced (three weep holes per each section of horizontal mullion between vertical mullions, typically), and drainage at every horizontal frame (do not use vertical frames to drain past horizontal frames). Use as many 1/4-inch by 2-inch slots as required for pressure-equalized systems. Design the drainage system to handle condensation as well as rain.

- Curtain wall perimeters should have flashings (sill, jambs and head) that are sealed to the air and water barrier at adjacent walls. Slope head and sill flashings to the exterior to promote drainage. Integrate curtain wall sill flashings with sill flashings or base of wall flashings of adjacent walls. Curtain wall should have a primary air/water seal between the shoulder of the tube at the plane of the glazing pocket and the air barrier of the adjacent construction.

- Perimeter sealants are useful as a rainscreen for limiting air and water penetration through the outermost plane of the wall, but should not be relied upon as the sole air/water penetration barrier.

- Coordinate placement of setting blocks with weep holes to avoid blocking drainage paths.

Glazing Methods and Their Impact on Performance

Pressure Plate Glazing: In this system the glass and infill panels are installed from the exterior, typically against dry gaskets. The outer layer of gaskets is installed and the gaskets are compressed against the glass by the torque applied to fasteners securing a continuous pressure plate. The plate is later typically covered with a snap-on mullion cover. This system provides reasonable performance but is susceptible to leaks at corners or joints in dry gaskets. For improved performance four-sided gaskets can be fabricated at additional cost or wet sealants can be installed to provide a concealed interior toe bead or exposed interior cap beads. Pressure plate glazing allows the easiest method to seal an air barrier from adjacent construction into the air barrier of curtain wall system.

Interior Dry Glazing: In this system the glass and infill panels are installed from the interior of the building, eliminating the need for substantial scaffolding and saving money. The frame is fixed and exterior dry gaskets are installed. Typically only the top interior mullion has a removable stop. The glass unit is slid into a deep glazing pocket on one jamb far enough to allow clearing the opposite jamb and is then slid back into the opposite glazing pocket and then dropped into the sill glazing pocket. The removable interior stop is installed and finally an interior wedge gasket is forced in. Sometimes this method is called "jiggle" or "wiggle" glazing because of the manipulation necessary to get the glass into place. Performance is slightly reduced because dry metal to metal joints occur at the ends of the removable stop at a point that should properly be air and watertight. Wet sealant heel beads will improve performance and some systems include an extra gasket to form an air barrier seal. Installation of spandrel panels may need to be installed from the exterior.

Structural Silicone Glazing: In this system the glass or infill unit is adhered to the frame with a bead of silicone. Outer silicone weather seals supplement the structural seal. Unitized systems are frequently structural silicone glazed, especially if four-side SSG is desired. Two-sided SSG, with pressure plate glazing or wiggle glazing on the other two sides is acceptable to be field installed.

Butt-Glazing: SSG is frequently mistakenly referred to as butt-glazing. True butt-glazing has no mullion or other back-up member behind the joint and relies solely on a sealant, typically silicone, between the glass units to provide a perfect barrier seal.

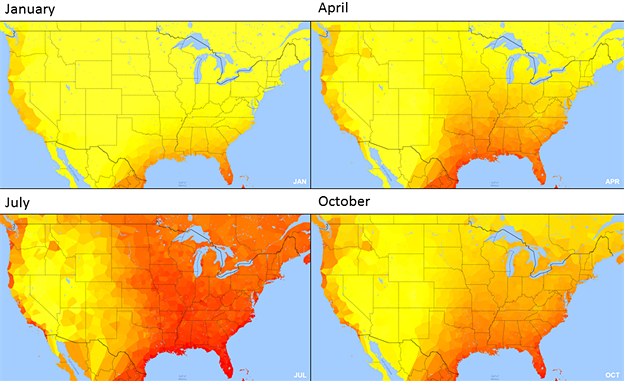

Designing for Condensation Resistance

AAMA's Curtain Wall Design Guide provides guidance on window selection for condensation resistance. Establish the required Condensation Resistance Factor (CRF) based on anticipated interior humidity and local climate data and select a curtain wall with an appropriate CRF. Designers should be aware that the CRF is a weighted average number for a curtain wall assembly. The CRF does not give information about cold spots that could result in local condensation. Projects for which condensation control is a critical concern, such as high interior humidity buildings, require project-specific finite element analysis thermal modeling using software such as THERM. Careful analysis and modeling of interior conditions is required to accurately estimate the interior temperature of the air at the inside surfaces of the glass and frame. Curtain walls that are set well outboard of perimeter heating elements will have air temperatures along their interior surface that are significantly lower than the design wintertime interior temperatures. Thermal modeling of the building interior using Computational Fluid Dynamics (CFD) software can help establish a reasonable estimate for air temperatures at the inside surfaces of the glass and frame. These interior air temperatures are inputs for the thermal modeling software. Include lab mock-up thermal testing in addition to CFD modeling for analysis of project-specific conditions. Unusual or custom details, such as copings, deep sills, projected windows, spandrel areas and shadow box can dramatically alter performance.

Use thermally broken or thermally improved aluminum frames for best performance. At the perimeter of the curtain wall, the thermal break must be properly positioned with respect to the wall system/insulation to avoid exposing the aluminum frame inboard of the thermal break to cold air ("short circuiting" the thermal break). Special insulation provisions may be required where curtain walls project beyond adjacent cladding systems (e.g., an insulated perimeter extrusion or metal panning).

Consider frame geometry for thermally conductive aluminum frame materials. Minimize the proportion of framing exposed to the outdoors.

Refer to AAMA 1503 for descriptions of test method, parameters and equipment for determining U factors and CRF's for window products. Refer to NFRC 100 for U Factor and NFRC 500 for condensation resistance.

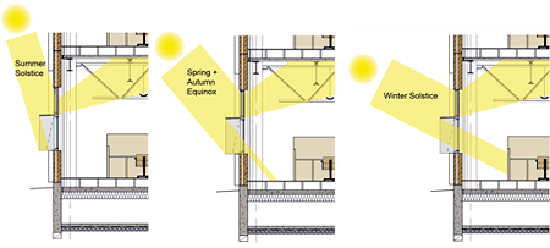

Designing for Solar Heat Gain Control and Solar Optical Properties

The use of glazed curtain walls can present challenges in balancing the desire for more natural daylight versus addressing the heat gain typically associated with such systems. Occasionally, there are concerns relating to having too much uncontrolled daylight, sometimes referred to as glare. The challenge is to strive for the highest visible light transmittance (VT) and the lowest solar heat gain coefficient (SHGC) while not preventing the glass from being too reflective when viewed from both the exterior and the interior, while controlling glare. This glass performance data are obtained from data using the Lawrence Berkeley National Laboratory (LBNL) Window 5.2 program with Environmental Conditions set at NFRC 100 criteria. NFRC 200 is used to determine the VT and SHGC values while the solar optical properties are determined using NFRC 300. Typically, for products more widely available on the market, the aforementioned values are readily available from glass manufacturers/fabricators.

Designing for Finish Durability

Aluminum: Class I anodic coatings (AAMA 611, supersedes AAMA 606, 607 and 608) and high performance factory applied fluoropolymer thermoset coatings (AAMA 2605) have good resistance to environmental degradation.

Unitized Systems

Unitized systems are typically custom designed. There isa wide range of systems on the market from manufacturers that provide varying levels of reliability. Unitized systems range in performance ability from industry standard to high performance walls. It is thus recommended that projects specifying unitized curtain wall systems incorporate a team member who has a breadth of experience in designing and working with unitized systems.

Unitized systems are typically pressure equalized rain screen systems. The units should be completely assembled in a factory and shipped to the site for installation on the building. The units are placed on the floors, bundled in crates, using the tower crane and lowered into place using a smaller crane or hoist owned by the glazing contractor. The mullion dimensions tend to be slightly larger than a stick system due to their open section as compared to the tube shape of a standard stick curtain wall section. The advantages of the unitized system derive from the more reliable seals achievable from factory construction and the reduced cost of labor in the factory versus that of high rise field labor. Units can be assembled in a factory while the structural frame of the building is being constructed. Where stick systems require multiple steps to erect and seal the wall, unitized walls arrive on the site completely assembled allowing the floors to be closed in more quickly. Unitized systems also require less space on site for layout thus providing an advantage for urban sites with space limitations.

Unitized systems generally rely on rain screen design principles and gaskets and/or the interlock of mating frames for moisture protection at joints between adjacent modules. The interlocking vertical mullions will typically have two interlocking legs. One leg will be in the plane just behind the glazing pocket and the other at the interior face of the mullions. The interlocking leg in the plane of the glazing pocket will be sealed by gaskets and is the primary line of defense against water and air infiltration. More robust systems will also include a gasket at the interior interlock. Systems whose connecting legs lock also compromise the ability of the system to accommodate movement. Some unitized designs are sensitive to small irregularities in the spacing of adjacent modules; for example, if the module joints are slightly out of tolerance, gaskets may not be properly compressed and moisture protection may suffer. Robust designs include multiple lines of defense, realistic tolerances and adjustability for erection of modules.

The four-way intersection refers to the location where four adjacent units meet. This is where field labor must seal between adjacent units to achieve a weather tight wall. The interlocking legs of the horizontal mullions are the most critical interface of a unitized system. Water that infiltrates the interlocking vertical mullions drains to the interlocking horizontals that must collect and divert this water to the exterior. The top horizontal mullion of a unit incorporates upstanding vertical legs that mate with cavities in the bottom horizontal of the unit above. These upstanding legs have gaskets that seal against the walls of the bottom horizontal. Some designs provide one upstanding leg that provides one line of defense against air and water infiltration. More robust systems will provide two upstanding legs with gaskets on both legs. A splice plate or silicone flashing that is installed at the top of the two adjacent units as they are erected on the building is typically required.

The vertical mullions of unitized systems typically anchor to the slab edge as they pass by. The stack joint is the horizontal joint where units from adjoining floors meet. Placing the stack joint at the sill of the vision glass (typically 30" above the floor) will minimize the dimension of the vertical mullions. This positioning utilizes the back span of the mullion above the anchoring point at the slab to counteract the deflection of the mullion below the slab. Also placing the stack joint above the floor provides a more convenient location for field workers to achieve the critical seal at the four-way intersection.

While two story spans are feasible, the weight of the unit is doubled which may require increased structural capacity to accommodate the increased load. Wind load bracing should be incorporated at the single span height to avoid increasing the vertical mullion dimension to accommodate the increased span. Steel can be added to a unitized system to increase its spanning capability. However, unlike a stick system which has an integral hollow shape, the split mullions must be allowed to move independently to accommodate the building movement thus complicating the introduction of steel. Large units may also increase transportation costs from the factory to the site and erection costs of placing the units on the building.

Thermally broken unitized systems are available, utilizing similar technology as that used in stick curtain wall systems.

Logistical and Construction Administration Issues

The service life of even the most durable curtain wall may be shorter than that of durable adjacent wall claddings such as stone or brick masonry. Therefore, the design of the curtain wall and perimeter construction should permit curtain wall removal and replacement without removing adjacent wall components that will remain.

The service life expectancy of components that are mated with the curtain wall into an assembly should match the service life expectancy of the curtain wall itself. Require durable flashing materials, non-corroding attachment hardware and fasteners, and moisture resistant materials in regions subject to wetting.

Laboratory testing: For projects with a significant amount of custom curtain wall, require laboratory testing of a mock-up curtain wall prior to finalizing project shop drawings. Have a curtain wall consultant present to document mock-up curtain wall construction and verify mock-up performance. Specify that laboratory tests are to be conducted at an AAMA Accredited Laboratory facility.

Field Mock-up: For all curtain walls, stock or custom, require construction and testing of a field mock-up representative of the wall/window assembly. This is best scheduled prior to the release of shop drawings for window production, so that there is an opportunity to make design changes based on the test performance of the field mock-up. Specify that field tests be conducted by an independent third party agency accredited by AAMA.

Field testing of curtain walls: Require the field testing of curtain walls for air infiltration and water penetration resistance, for quality assurance of curtain wall fabrication and installation. Require multiple tests with the first test on initial installations and later tests at approximately 35%, 70% and at final completion to catch problems early and to verify continued workmanship quality. Require additional testing to be performed if initial tests fail.

Shop drawing coordination: Require curtain wall installation shop drawings showing all adjacent construction and related work, including flashings, attachments, interior finishes, and indicating sequencing of the work.

Curtain wall systems, especially unitized systems, require expertise on the part of the building designer, the manufacturer, the fabricator, and the installer. For all but the simplest of systems, the designer should consider engaging an outside consultant, if such expertise is not available on the staff.

Details

The following details can be viewed online in Adobe Acrobat PDF by clicking on the PDF to the right of the drawing title.

The details associated with this section of the BEDG on the WBDG were developed by committee and are intended solely as a means to illustrate general design and construction concepts only. Appropriate use and application of the concepts illustrated in these details will vary based on performance considerations and environmental conditions unique to each project and, therefore, do not represent the final opinion or recommendation of the author of each section or the committee members responsible for the development of the WBDG.

Note: the following S-series details are courtesy of Richard Keleher Architect

Typical Elevation—Stick-Built Curtain Wall-Pressure Equalized-Outside Glazed (Figure S – 1) PDF

This elevation shows a typical stick-built curtain wall set in a punched opening in a masonry cavity wall.

- Elevation includes splice joints to accommodate thermal movement of the curtain wall frame.

Curtain Wall Head—Stick-Built System-Pressure Equalized-Outside Glazed (Figure S – 2) PDF

- A through-wall metal flashing at the base of the brick cladding above the curtain wall protects the curtain wall from leakage through the wall above— (see Exterior Wall) for integration of the these components.

- Locate exterior perimeter sealant joints behind trim cover to prevent water inside trim cover from bypassing the exterior sealant joint.

Curtain Wall Jamb—Stick-Built System-Pressure Equalized-Outside Glazed (Figure S – 3) PDF

- Locate exterior perimeter sealant joints behind trim cover to prevent water inside trim cover from bypassing the exterior sealant joint.

Curtain Wall Sill—Stick-Built System-Pressure Equalized-Outside Glazed (Figure S – 4) PDF

- Continuous metal sill flashing at the base of the curtain wall protects the wall framing below from leakage through the curtain wall. Sill flashing should have upturned end dams and fully sealed corners.

Intermediate Mullion—Stick-Built System-Pressure Equalized-Outside Glazed (Figure S – 5) PDF

- Intermediate horizontal should be wept to the exterior and prevent water from draining onto the head of the glazing unit below. Care must be taken to ensure all corner frame joints in the glazing pocket are sealed to prevent leakage to the interior.

- Locate setting blocks as to not obstruct water drainage from the glazing pocket.

- Provide anti-walk blocks at the jambs of the glazing units. Blocks should be gapped 1/8-inch from the edge of the glazing unit.

Isometric of Finished System—Stick-Built System-Pressure Equalized-Outside Glazed (Figure S – 6) PDF

Isometric of Curtain Wall Sill—Stick-Built System-Pressure Equalized-Outside Glazed (Figure S – 7) PDF

Isometric of Vertical Curtain Wall Mullions—Stick-Built System-Pressure Equalized-Outside Glazed (Figure S – 8) PDF

Elevation of Horizontal Pressure Plate—Stick-Built System-Pressure Equalized-Outside Glazed (Figure S – 9) PDF

Note: the following U-series details are courtesy of The Facade Group

Isometric of System Assembly Unitized Curtain Wall System (Figure U–1) PDF

This elevation shows a typical unitized curtain wall assembly hung from the edge of the floor slab.

- Differential movement between curtain wall units is accommodated at the vertical and horizontal unit joints.

- The unit shown is composed of vision glazing and a glazed spandrel shadow box with an insulated back pan.

Isometric of Open Stack Joint Unitized Curtain Wall System (Figure U–2) PDF

- A continuous vertical gasket provides the primary weather seal at the pressure equalized rainscreen zone of the assembly.

- Foam glazing tape weather seal is discontinuous at horizontal panel joints to achieve pressure equalization between weather and air seals at vertical unit joints.

- A splice cover is applied over the horizontal stack joint between units to provide continuous waterproofing behind and below the pressure equalized wet zone of the vertical stack joint.

- The units are connected with a field applied splice sleeve that contains an index clip to align the next unit above the joint horizontally as it is being set.

Isometric of Completed Stack Joint Unitized Curtain Wall System (Figure U–3) PDF

- Glazing pocket weeps are protected from wind-driven rain and pressure by a glazing trim cover containing weep slots in the bottom which are offset from the sill glazing pocket weep slots and the glazing setting blocks at glazing panel quarter points.

- The primary air and water seal at the stack joint should have sufficient height and drainage to prevent water head from overtopping the gaskets. Gasket height should correspond to the curtain wall design pressure.

- Exterior cover splice sleeves are installed at the face of the stack joint during unit field installation.

Vision Glass Jamb Unitized Curtain Wall (Figure U–4) PDF

- Units are designed and installed with horizontal and vertical clearance gaps to allow for differential movement and accommodate construction tolerances.

- Pressure equalized rainscreen gaskets form a primary weather seal at the face of the unitized vertical stack joint in line with the horizontal rainscreen gasket at the unit sill below.

Unit Stack Joint Unitized Curtain Wall (Figure U–5) PDF

- Single or double glazing can be used at the spandrel area which is backed by a finish metal panel to form a shadow box.

- Spandrel glass adapters are used to reduce the depth of the glazing pocket to accommodate reduced profile of spandrel glass. Spandrel glass adapters should be fully bedded in sealant and integrated with glazing pocket corner seals to prevent water leakage from glazing pocket to building interior.

- Unit dimension of mating head and sill extruded profiles allows for specified floor to floor deflection at the stack joint.

Intermediate Horizontal Unitized Curtain Wall (Figure U–6) PDF

- Intermediate horizontal members provide for divisions between vision panels or between vision and opaque or spandrel panels.

- Intermediate horizontals stop at the face of the vertical unit jamb members at each end.

Jamb at Spandrel Area with Anchorage to Slab Unitized Curtain Wall (Figure U–7) PDF

- Units are hung from the top or face of the adjacent floor or building structure using mated brackets and field applied bolts with a minimum of clearance for access and assembly.

- All connections and brackets located within the units insulated or primary weather seal zones are sealed with appropriate sealant materials during field installation.

Unit Anchor to Slab Edge Section Unitized Curtain Wall (Figure U–8) PDF

- Floor and ceiling closure is provided for fire and acoustical separation using code approved assemblies.

Emerging Issues

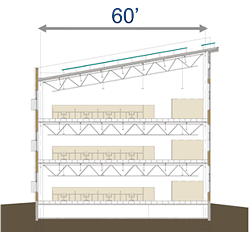

"Smart" Curtain Walls, like smart windows, control visible light transmittance by employing electrochromic or photochromic glass coatings; see the discussion in Glazing. Double-skin systems, which employ a ventilated space between the inner and outer walls are rare in the U.S., but have been constructed in Europe and Asia where energy costs are much higher. Similar in concept to air-flow windows, the ventilated space is intended to conserve energy by modulating the temperature conditions inboard of the curtain wall. During the heating season, the space acts as a buffer between the exterior and interior, and can be used to temper outdoor supply air. During the cooling season, warm interior air is exhausted into the space. There is currently discussion among building science experts that, at least for cold climates, a less expensive way of achieving energy savings might be through the use of curtain walls with high (over R-6) insulating values. Point-supported glass, structural glass mullions and use of tension structures are recent technologies.

Relevant Codes and Standards

Curtain Wall Design and Selection

Thermal Performance

Solar Heat Gain Coefficient

Solar Optical Properties

Air Infiltration

Water Penetration Resistance

Condensation Resistance Factor

Seismic Loads

- AAMA 501.4 & 501.6 Recommended Static Test Method for Evaluating Curtain Wall and Storefront Systems Subjected to Seismic and Wind Induced Interstory Drifts and Recommended Dynamic Test Method For Determining the Seismic Drift Causing Glass Fallout from a Wall System

Structural Uniform Loading by Static Pressure

Acoustical Performance

Anodized Coatings

High Performance Organic Coatings

Additional Resources

WBDG

Design Objectives

Functional / Operational—Ensure Appropriate Product/Systems Integration

Products and Systems

Building Envelope Design Guide—Glazing, Building Envelope Design Guide—Windows, See appropriate sections under applicable guide specifications: Unified Facility Guide Specifications (UFGS), VA Guide Specifications (UFGS), Federal Guide for Green Construction Specifications, MasterSpec®

Organizations

NOTE: Photographs, figures, and drawings were provided by the original author unless otherwise noted.