BRII2/BRAR2/TLTS2 - Bedroom, ICU/CCU, Protective Environment with Anteroom, ICU/CCU, Protective Environment and Toilet/Shower

BRNP2/TLTP3 - Bedroom, Behavioral Health (Double Occupancy) with Toilet/Shower, Behavioral Health

BRNP5/BRNP6/TLTP2 - Seclusion Room - Anteroom, Seclusion - Toilet, Seclusion

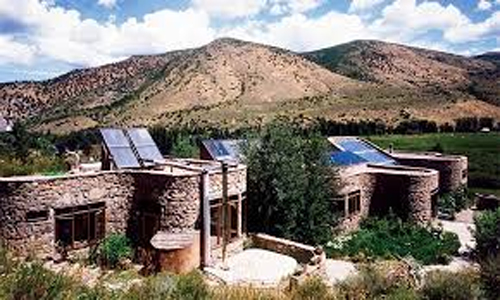

Brock Environmental Center

View of the Brock Center from the marshes and Bay to the South. Students and residents can access the waterways to develop a deeper understanding of the Bay's threatened ecosystems. Photo Prakash Patel Photography, courtesy of SmithGroupJJR.

Building Commissioning: The Process

Introduction

Within This Page

Building commissioning (Cx) is a professional practice that facilitates the planning, design, construction, installation and testing verification, documentation, and operation of facilities and systems to conform to the Owner's Project Requirements (OPR).

Building commissioning comprises specific phases and activities for both new construction and existing buildings. Whether commissioning new construction or existing buildings, the process includes many incremental activities, usually team-based functions that result in project-specific benefits and documentation.

Cx is the ONLY profession/entity, other than the owner, that is engaged throughout the process of design, construction, delivery, and optimizing performance of facilities. CxPs require a substantial amount of knowledge, skills and experience to be able to recognize, address, and even correct issues, and building/systems performance, through the eyes of every other team member and throughout the project.

This 8–page section of the Whole Building Design Guide (WBDG) presents overall commissioning process information, guidance, challenges, and resources. The first 4 pages are focused primarily on new construction commissioning, followed by pages 5 and 6 which outline the process and guidance for commissioning existing buildings whenever it occurs from initial occupancy through the life of the facility. Pages 7 and 8 describe challenges and further resources for owners, designers, contractors, commissioning providers (CxP), and consultants.

- Building Commissioning: The Process

- Determining Project Performance Requirements

- Roles and Responsibilities in the Commissioning Process

- Commissioning Documents: Process, Contents, and Acceptance

- Existing Building Commissioning

- Ongoing Commissioning

- Commissioning Challenges and Emerging Issues

- Additional Commissioning Resources

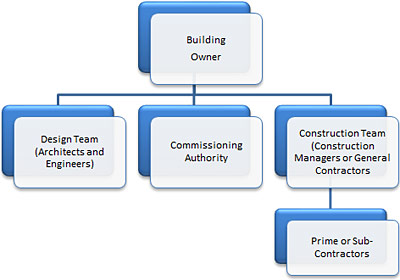

Building Commissioning requires a detailed and team oriented process.

Commissioning Benefits and Goals

The ultimate benefit of new facility and system commissioning is the documented performance of the facility and systems as it is transitioned into the long-term operations and maintenance function. Commissioning, used as a more forensic problem identification and solutions-based process, can be applied to an existing facility or system even if not initially commissioned, as described in Existing Building Commissioning.

Commissioning assists in the delivery of a project and helps to provide an efficient, safe and healthy facility; optimizes energy and water use; reduce operating costs; facilitate O&M staff orientation and training; and improve installed building systems documentation and operations. These functions can result in increased profitability in both facility and staff operations.

Commissioning benefits Owners through improved facility performance including higher quality workplace environments, and prevention of potential business losses. The cost of not commissioning is equal to the increased costs of correcting design and construction deficiencies later, plus the costs of inefficient operations. For example, in mission critical facilities, the cost of not commissioning can be measured by the cost of downtime and lack of appropriate facility use.

The primary goal of commissioning any project or system is to ensure that success for the project is clearly defined in the Owner's Project Requirements (OPR) and that the building and systems perform as intended to fulfill that mission. The commissioning process can be applied to an entire facility or to any specific system or assembly if new, upgraded or modified.

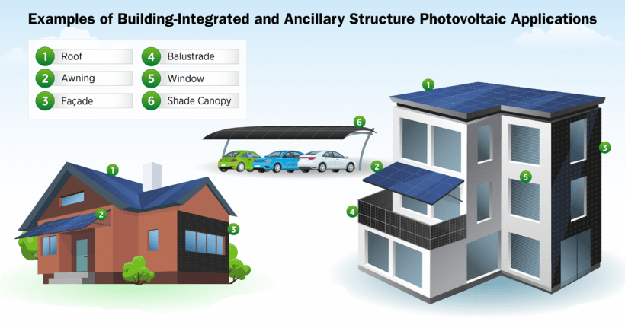

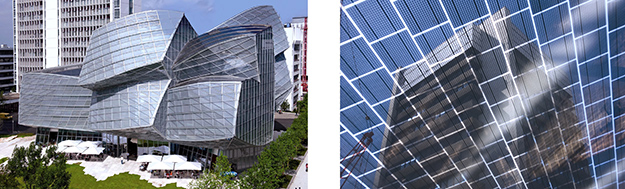

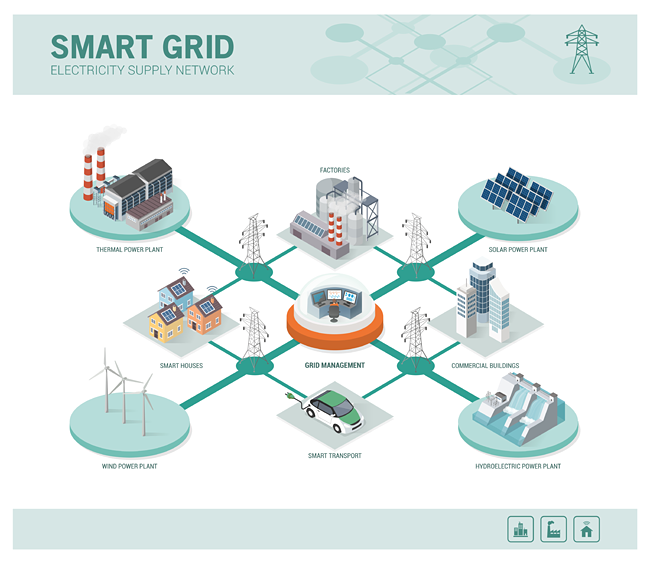

In addition to energy efficiency and overall performance drivers, another factor increasing demand for commissioning is the Owner's desire to obtain certification through building performance rating systems. These rating systems have been developed to improve the project planning, design, construction, and performance of energy and water efficiency, environmental conditions in buildings, verification, documentation, and operations practices. A building certified to these rating systems can include highly efficient gas, water, power and lighting systems, solar photovoltaics, and other energy and resource technologies. From an Owner's perspective, investment in these and other sophisticated building technologies must be accompanied by rigorous design and construction quality assurance and performance verification measurement, which are provided holistically through the commissioning process.

The principal goals of building commissioning are to:

- Include the project requirements including the commissioning process in the OPR document.

- Verify that the OPR requirements, including commissioning, are in the project design and construction documents for new projects.

- Facilitate delivery of buildings and construction projects that meet the Owner's Project Requirements.

- Prevent or eliminate problems in a cost-effective manner through proactive quality techniques.

- Verify systems are installed and working as intended and benchmark that operation.

- Provide and collect documentation and records on the design, construction, and testing to facilitate operations and maintenance of the facility.

- Facilitate training functions and system operation documentation and Cx tools for O&M staff performance and implementation of ongoing Cx.

- Lower overall first costs and life-cycle costs for the Owner.

- Maintain facility performance for the building's entire life cycle.

Commissioning Definitions

Commissioning definitions vary slightly based on the project phases and the function of the Cx process in the specific sequence. The commissioning process can be implemented on an entire facility or on specific systems or assemblies as required by the Owner and project.

The following definitions depict commissioning as a holistic process that spans from pre-design planning to occupancy and operations at a minimum and should also include ongoing commissioning. As stated in ASHRAE Standard 202–2018: Commissioning Process for Buildings and Systems, the following definitions are provided:

Commissioning Process (Cx) — all, including New Construction (NCCx): a quality-focused process for enhancing the delivery of a project. The process focuses on verifying and documenting that all of the commissioned systems and assemblies are planned, designed, installed, tested, operated, and maintained to meet the OPR.

Existing-Building Cx (EBCx): a quality-focused process for attaining the Current Facility Requirements (CFR) of an existing facility and its systems and assemblies being commissioned. The process focuses on planning, investigating, implementing, verifying, and documenting that the facility and/or its systems and assemblies are operated and maintained to meet the CFR, with a program to maintain the enhancements for the remaining life of the facility. See Existing Building Cx.

Retro-commissioning (RCx) is commissioning an existing building that has never been commissioned before.

Recommissioning (ReCx) occurs when a building that has already been commissioned undergoes another commissioning process. The decision to recommission may be triggered by a change in building use or Ownership, the onset of operational problems, or some other need.

Monitoring-Based Commissioning (MBCx) utilizes primarily monitored data (versus primarily manual tests and checks) originating from the Building Automation System (BAS) or other meters processed with special analysis tools, sometimes referred to as Energy Management and Information Systems (EMIS).

System-Specific Commissioning is a tailored application focused on a small subset of targeted systems in a building, such as indoor environmental quality or chiller plant efficiency.

Ongoing Commissioning (OCx) continuously gathers data about existing systems and building performance and continuously or regularly evaluates the data to ensure proper operation and to improve performance, usually dependent on hardware and software tracking tools and by a separate contractual arrangement after completion of NCCx or EBCx.

Description

The commissioning process ideally begins at project inception (predesign phase) and continues in phase-specific functions through facility and system operation. It is not a design or construction function, but it assists in and verifies that the results of these functions can produce a facility and systems that meets the requirements for performance. Depending upon the Owner's needs, these might include; functionality, efficiency, sustainability, environmental and health impacts, interior occupancy conditions, resilience, and others that will maximize facility and system profitability for the Owner and the occupants.

Commissioning for new construction typically involves a CxP for all phases until the building is occupied:

Phase 1 — Predesign. It is important to start the commissioning process in the pre-design phase. This early involvement by the CxP is critical for the timely and useful development of the Owner's Project Requirements (OPR), the subsequent design team Basis of Design (BOD), the Commissioning Plan, and the beginning of the Operations & Maintenance (O&M) Systems Manual. If these tasks are left until later in the process and "reverse engineered" to match the design, their usefulness as catalysts for dialog, cost and risk management, and quality tracking tools is lost.

Phase 2 — Design. During the design phase the project design and details are further developed and organized for the construction documents. These documents must be based on the design team's application of the OPR. If questions and variations to these requirements evolve during this phase, it may be necessary to update the OPR with the acceptance of the Owner or representative. The commissioning requirements are further developed during design including the selection of the systems to be commissioned and the specifications detailing the functions of commissioning and the contractor's and manufacturers responsibilities as part of the commissioning team. The commissioning plan is further developed during the design phase to reflect the design and performance requirements of the commissioned systems and the initial development of field observation, functional testing, and performance requirements, along with documentation formats for testing and reporting. During and at the conclusion of project design, the CxP reviews the construction documents to determine compliance to the OPR and inclusion of the commissioning requirements. The CxP design review is intended to verify compliance with the OPR and is not considered a PEER review. Any open issues should be responded to in writing from the designer for design completion.

Phase 3 — Construction. In the construction phase, the commissioning process transitions from planning to application and is active during the entire construction phase. During pre-construction, the commissioning schedules are developed and integrated into the construction schedules. The CxP reviews the submittals for the commissioned systems and further develops the field observation, testing, and functional and performance requirements and checklists in the commissioning plans. The commissioning team is assembled along with the general contractor and relevant sub-contractors, manufacturers, and suppliers and these Cx Team members participate in a project commissioning scoping meeting for training and coordination. Subsequent meetings are conducted as needed, including systems integration meetings for both building controls and other building alarm and operating systems. An issues and resolution log is created by the CxP to communicate problems, concerns, and questions during the project to the Cx team and Owner. This log is updated during the project and the final log is included in the commissioning report. Depending upon the project organization, normally the contractors complete the installation field observations and checklists as required by the commissioning plan. These completed checklists are reviewed by the CxP and any needed adjustments are performed on the Functional Performance Tests (FPT) and schedules. In coordination with the construction schedules, the FPTs are conducted by the contractors along with the CxP as a witness. Based on FPT results, a preliminary commissioning report is drafted and reviewed by the Owner and, if necessary, the local jurisdictions. Any necessary plans for deficiency correction and off-season testing are included.

Reviewing the construction documents and coordinating with the construction team to ensure proper implementation of the project and commissioning plan. Photo Credit: 33684514, Ndoeljindoel/Dreamstime.com

Phase 4 — Hand-Off/Occupancy. At project substantial completion and after conducting operations and maintenance training by the design team (if applicable), contractors, and suppliers, the Owner assumes operational responsibilities for the facility or project. The commissioning process is not complete until the off-season testing is completed and the systems manual is completed and transferred to the Owner. At that time, a final commissioning report is developed including the final issue logs with any open items as accepted by the Owner.

NEW CONSTRUCTION/SYSTEM COMMISSIONING DOCUMENTATION

The new construction commissioning process includes multiple activities performed in a specific sequence. As defined in ASHRAE Standard 202–2018, Commissioning Process for Buildings and Systems, these functions are required to provide a complete commissioning project.

Initiation: The Owner or Owner's representative initiates the commissioning process at the beginning of the project. The roles and responsibilities of the project and commissioning teams are determined. Procedures and contracts are prepared and executed.

Owner's Project Requirements: Next, the project requirements are determined and documented which include the building program, use, scope, and the requirements for performance, sustainability, resiliency, training, testing, commissioning, and documentation. The deliverable for this activity is the Owner's Project Requirements (OPR) document which is the guiding instruction for the project. The OPR is updated throughout the design and construction of the project. See Determining Project Performance Requirements for further information on assembling the OPR.

Commissioning Plan: The initial Commissioning Plan is developed by the CxP that identifies the commissioning scope, roles and responsibilities, communication procedures, and design and construction requirements for providing and integrating commissioning into the project. The Commissioning Plan is updated throughout the project with checklists, schedules, and documentation details. The Owner reviews and accepts this plan.

Basis of Design: The design team determines and documents the design approach to meet the Owner's Project Requirements resulting in the Basis of Design (BOD) document. The CxP reviews the Basis of Design for conformance to the OPR. The Owner reviews and accepts this document before design completion.

Specifications: During the design phase, the contractor commissioning requirements are determined for each system and included in the commissioning specifications for the construction documents package.

Design Review: In the design phase, the CxP reviews the design and documents for conformance to the OPR. This design review also provides details that facilitate the further development of the commissioning plans.

Submittal Review: The commissioning team reviews the materials and equipment submittals for conformance to the OPR and construction documents. The submittals also provide information and details to develop project and commissioning process checklists.

System Verification: As the project is constructed, the commissioning team observes and verifies the installation and performs or witnesses the equipment start up and initial testing. Checklists and reports are prepared as required by the commissioning plan.

Functional Performance Testing (FPT): Functional and performance testing is conducted according to the commissioning plan to verify performance compliance with the OPR and design documents.

Issues and Resolution Log: Issues and resolution of issues are identified and documented by the commissioning team in the Issues Log along with related documentation. This log is a communication device for questions and problems from all the commissioning team participants that need solutions to facilitate successful project completion.

Systems Manual: During the design and construction of the project, the design and construction and verification documents are assembled into the systems manual. This assembly is normally performed by the general contractor or PM. This assembly of documents provides the details and history of the design and construction of the building and information needed to properly operate and maintain the building. The commissioning reports are included in the final Systems Manual.

Training: Training of facility staff should be pervasive throughout the commissioning process. At the hand-off/turnover phase, formal training ensures that operations and maintenance staff understand the equipment and systems. Training activities ensure that operators understand the theory ("why") as well as how to control and maintain the systems ("how") to operate and use the building in accordance with the OPR and design capabilities, the building operational staff and users are trained on the installed equipment and systems.

Seasonal or Deferred Testing: Commissioning activities that were not performed due to climatic conditions or equipment availability before initial certificate of occupancy are conducted during post occupancy. The final testing results are included in the final commissioning report and systems manual.

Commissioning Report: At the time of granting a facility Certificate of Occupancy a preliminary commissioning report is prepared that shows the commissioning progress and equipment performance to date. At the completion of the project, the final commissioning report is assembled and provided to the Owner and others as required by the OPR and local jurisdiction requirements.

Careful observation is an essential component of the documentation process during commissioning.

COMMISSIONING PROCESS MANAGEMENT

The facility or project Owner, or representative, defines and manages the process and reviews the documents. During project planning, the Owner also defines the extent and requirements of the commissioning process along with the basic commissioning team functions and responsibilities. Those functions are further defined in Roles and Responsibilities in the Commissioning Process.

The CxP normally reports to the Owner or Owner's Representative. This relationship and the contract need to be established at the beginning of the project. The function of commissioning is to assure the Owner that they are receiving true and full value in the function and performance of the commissioned systems. Thus, the reporting relationship to the Owner reduces or eliminates the possibility of a conflict of interest by the CxP.

Application

Building and/or System Commissioning Initiation

Engaging the CxP at the beginning of the project allows the CxP to become familiar with programming documents and proceed immediately to the OPR workshop and the development of the whole building criteria that match the project needs including facility certifications such as LEED®, Green Globes, Living Building Challenge, WELL, among others, and jurisdictional requirements. The OPR should be developed during the pre-design phase. When developed first, the OPR can become a very useful tool to the Owner in selecting the correct design and construction team for the project. During the selection process of the design team, candidates' responses to the OPR when submitting their BOD provides tremendous insight into their understanding of the OPR.

When the Systems Manual requirements are also started at this early stage, the inclusion of O&M requirements is facilitated. The inclusion of O&M planning in the early phases is key to the long-term persistence of energy efficiency, equipment longevity, and whole building performance strategies built into the design.

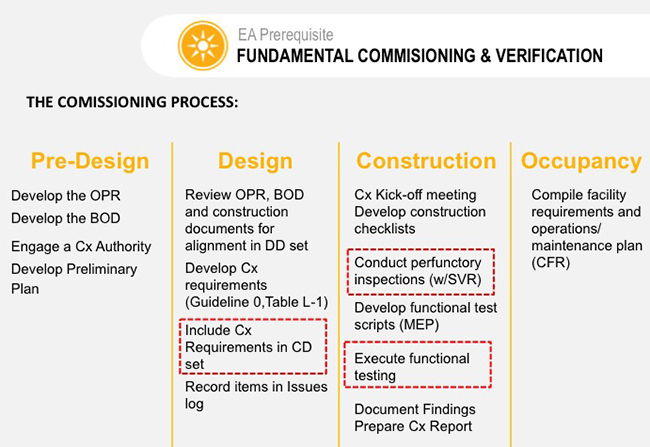

Sample commissioning process as outlined in ASHRAE Guideline 0 that informs NIBS Guideline 3, the basis for LEED Enclosure Commissioning. Photo Credit: USGBC

Determining Project Performance Requirements

Every new project goes through pre-design and design phases that establish an Owner's needs, goals, scope, and design solutions for a proposed project. Proposed designs and constructed work can only be evaluated against objective criteria and measures that are embodied in a well-documented OPR. Project development is a learning process where building performance decisions are refined to successive levels of detail over the course of a project's life cycle. This may also include possible future programs such as solar, recycling, and new technology.

The project performance requirements are defined and assembled in the OPR document. The OPR is also the foundation document of successful Cx. It is critical in ensuring the commissioning process meets the Owner's goals. The OPR defines the cost expectations, performance goals, energy and operational benchmarks, high-level schedule dates, operational approaches, and success criteria for the project. Owner staffing plans for the facility should be clearly identified so any impact on the design of the facility systems is known. The OPR must be developed with significant Owner input and ultimate acceptance. The CxP typically assists the Owner in identifying the facility's requirements regarding such issues as energy efficiency, indoor environment, staff training, and operations and maintenance. An effective OPR incorporates input early in the project from the Owner, operations and maintenance staff, and end users of the building, and is updated throughout the project. A properly developed and updated OPR truly becomes the definition of success for a project.

Defining Cx Requirements for a Project

The commissioning process can be applied to an entire facility or project or to limited and specific equipment and assemblies. The specific commissioning application is defined in the OPR. Subsequently creating the Commissioning Plan (Cx Plan) will answer the questions and set the criteria for the commissioning process on the project.

Key project requirements and related commissioning activities include:

- Establish goals for project quality, efficiency, certifications, and functionality of commissioned systems

- Establish a commissioning scope

- Establish commissioning budgets

- Assign team members and responsibilities

- Establish commissioning plans

- Establish commissioning schedules

- Establish testing and field observation plans

- Develop commissioning specifications

- Determine scope and content of commissioning documentation and reports

- Define special testing needs

- Develop Systems Manual format and requirements

- Determine operational staff training needs

- Establish ongoing building commissioning (OCx) plans and requirements

The project requirements and the systems and assemblies selected for commissioning determine basic commissioning functions and requirements. Additionally, the Owner can require variations and options in the requirements, such as sampling or specific testing, when needed on a specific function or project.

Project Documentation, Records, and Acceptance

The purpose of commissioning documentation is to serve as the historical record of the "what, why and how to" of key delivery team decisions throughout the planning and delivery process. Commissioning documents the establishment of standards of performance for building systems and verifies that designed and constructed work meets those standards. Key commissioning deliverables supporting Document Compliance and Acceptance are included above in the New Construction/System Commissioning Documentation section, and in Commissioning Documents: Process, Contents, and Acceptance.

Additional Resources

See the Additional Commissioning Resources page for more information.

Building Design Considerations in Cold Climates

Introduction

Within This Page

The content of this section of the BEDG in the WBDG is intended solely as a means to create awareness of the relevant topics and concepts. The following information is general in nature, consequently the application of the concepts discussed in real world conditions will vary based on project specific performance considerations and site specific microclimate conditions unique to each project, geographic location and building façade.

In the creative process of building design, a great deal of consideration is given to the physical landscape of a development. Orientation of the future building's footprint, entrances, exits, glazing, interior spaces, etc., are prudently arranged and manipulated to create the most aesthetically pleasing, efficient, and economical plan for the desired use of form and function.

This task of optimizing the readily observable attributes of a plan to its physical landscape can be a daunting task further complicated by the analysis of additional unseen non-physical factors. These factors often include the analysis or impact of: radiant solar angles, sun shadows, noise, vibration, wind force, air quality, pedestrian level winds, snow loading, etc. These last non-physical examples have been traditionally grouped into an area called Environmental or more accurately Microclimate Studies.

The term "microclimate" is defined by Merriam-Webster.com as: "the essentially uniform local climate of a usually small site or habitat". The purpose of conducting these non-physical studies is traditionally two-fold; first to understand the existing microclimate of the site from the various points of study; and secondly to predict the negative impacts, interaction, and influence of the proposed building design on the microclimate and modify the design to mitigate negative impact.

Consequently, the effort to create an aesthetically pleasing, efficient, and economical plan can have immense challenges and trade-offs. That said, the purpose of this particular resource page is to bring awareness to one specific non-physical microclimate factor for consideration in design: winter weather or winter precipitation and its potential for hazardous conditions to people and property if not adequately anticipated. Further it is important to note that the occurrence of hazardous winter ice and snow formations cannot be eliminated and can only at best be reduced in frequency or severity.

Description

The Problem Condition

The following text has been created to raise awareness of an old topic that is of growing concern based on some current trends in the economy and industry at large. Buildings in cold climates have struggled throughout the ages with ice and snow formations that slide, fall, or get windblown from their roofs, ledges, and window sills, causing harm to people and damage to property below. Sliding snow from residential roofs has damaged cars, blocked exits, or even torn off gutters and flashing details. On larger commercial or public buildings the issues are largely the same; however, the potential for damage or injury grows as building surfaces are larger, buildings are taller, and the volume of pedestrian and vehicular traffic increases.

In densely populated urban centers, such as New York City, Boston, Chicago, Toronto, Denver, and Washington D.C.; where prominent tall buildings are constructed on small sites with pedestrian and vehicular traffic mere feet from their base, the tolerance for any potential hazard or interruption of building operations due to falling ice and snow, or the erection of yellow "caution tape" is significantly less. Furthermore, experience has shown that public and urban buildings in general have very little tolerance for shedding ice or snow, regardless of the magnitude of the potential hazard, if it is thought that the occurrence will be perceived as a danger, or damage a building's reputation for safety. This leads to the question: what size of ice or snow piece is acceptable to fall from a building, and how often is it acceptable for ice or snow to fall?

Ice piece found on sidewalk that had fallen from a building ledge. Photo Credit: Northern Microclimate Inc.

A sight becoming far too common on city sidewalks in winter. Photo Credit: Northern Microclimate Inc.

At this time in the advancement of the study topic, the answer to those questions has not been agreed upon within regulatory organizations. Therefore, the best course of action is to seek knowledge and expert advice where possible.

The Art and Science of Ice and Snow Assessment

The assessment of ice and snow focusses on the totality of the winter microclimate in an effort to predict and mitigate a variety of impacts that include:

- falling snow prediction

- falling ice or freezing rain accumulations

- sliding or movement of ice & snow

- melt water control & icicle formation

- wind drifted snow formations

- windblown snow infiltration

- freeze thaw damage

- obstructed views from skylights & clearstory windows

A damaged barrier on a small building ledge. Photo Credit: Northern Microclimate Inc.

Different from a snow loading study, the assessment of ice and snow has no prescribed or regulated criterion, standard or procedure by building codes to assist designers or engineers. Furthermore, an ice and snow assessment focusses on events that would interrupt building operations, services, or create a perceived or real hazard to people or property, compared to snow loading studies that are focused mainly on structural integrity and the potential for failure at a prescribed criterion target. For example: in general, a 50–year return period design criteria for snow loading on a roof surface is prescribed by building codes and is considered acceptable by the established authorities, in regard to the potential for failure of a roof structure. However, there is no corresponding requirement for the acceptability (return period or otherwise) of a falling icicle, windblown ice or snow piece, or sliding ice and snow accumulation from a roof or façade surface.

The current state of the industry is largely due to the complexity of the issues and corresponding number of variables that need to be considered. Furthermore, the analysis and computational models that would be required to predict the potential for building designs to experience hazardous ice and snow formations is beyond the current capabilities of economic study. Thus, the industry must rely on experience-based assessments conducted by consultants having a broad knowledge and experience in: microclimate analysis, building science, cold climate testing, and field investigation.

Characteristics of an Ice and Snow Assessment

The assessment of the potential for ice and snow hazard is generally accomplished through a design review process that considers historical meteorological statistics, local topography and surrounding buildings or structures in combination with the proposed building design. This allows for the frequency, directionality, and severity of winter storm conditions on the site specific microclimate to be evaluated and expressed in terms of potentially problematic conditions. For example: which building façade will be most affected by strong winter winds during snowfall; which direction will freezing rain storms impact the proposed building most frequently; and, where on the exterior of the building are hazardous ice and snow accumulations most likely to form.

If potentially problematic ice or snow formations are anticipated, design modifications can be recommended to reduce the frequency and severity of hazards. The recommendations are typically derived from past experience, including cold room test results and research of previous successful designs and/or field studies. If there is limited knowledge of the performance of a particular design feature, material or the affecting microclimate condition with the corresponding design feature or material, the refinement and validation of a mitigation concept can be recommended. This process is typically accomplished by conducting a full-scale physical test in a controlled cold room environmental chamber. This type of testing can be costly, however it is necessary to allow for the creation of the specific microclimate conditions required (or in question) to validate and refine a mitigation strategy or concept before it is implemented.

To demonstrate the varied aspects of ice and snow assessment, the following topics are discussed:

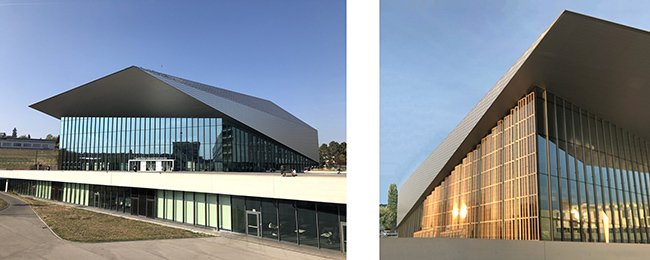

Building Geometries within their Microclimate

Once historical meteorological statistics have been reviewed and assessed in combination with the proposed building geometries, potentially negative influences of the building's performance within the local microclimate can be realized and improved upon. Examples of negative geometry and microclimate interactions can include:

- orientation of building form (long axis vs. short axis) or shape (curved, round or block forms, etc.)

- complex roof shapes that include slippery sloped surfaces, barrel vaults, roof steps, tower and podium interactions

- complex wall assemblies and sloped surfaces (double façades, trombe walls, complex curtain walls, etc.)

- locations of pedestrian access and/or exterior amenity areas such as courtyards, parking spaces, etc.

If these potential issues are identified and evaluated early in design, the risks of ice and snow hazard can be managed and improved upon, reducing their impact on cost and schedule, and resulting in more appealing aesthetics, as integrated mitigation designs can be investigated.

Envelope Design Considerations

Similarly, the ice and snow assessment can contribute to the decision process regarding envelope design. It is becoming evident that strategies to reduce energy consumption in buildings have a direct impact on the performance of the exterior building skin. Solar shading devices, high-performance wall assemblies and glazing products are generating significant energy savings in terms of long-term building heating and cooling requirements. However, these same strategies are having a negative influence on the accumulation and life span of ice and snow formations on façade surfaces. For example:

- the addition of exterior solar shading devices has significantly increased the exterior surface area available for ice and snow formation

- to obtain increased resistance to heat loss, exterior wall assemblies have in some cases increased in thickness thereby creating larger ledges and window sills

- high-performance glazing products have reduced heat loss thereby promoting increased volumes of ice and snow formations on glazing

An example of increased exterior surface area created by the addition of sun shades. Photo Credit: Northern Microclimate Inc.

An example of snow formation on curtain wall glazing.Horizontal shading device wraps around the façade of the Center. Photo Credit: Northern Microclimate Inc.

Roof

The roof surface of a building can be a complex region, not only in terms of geometry or the presence of skylights, mechanical equipment, etc., but in terms of ice and snow design. Snow load considerations for ice and snow formations on roof surfaces govern the structural design of the roof and can significantly influence the entire structural design down to the footings of a building. However, as previously discussed, the prescribed snow load process is focused on long-term safety and durability of the structure to avoid catastrophic failure, and is therefore less focused on issues that can influence day to day building operations, public perception and the potential for falling, windblown or sliding snow hazards from a building.

Given these differences, there are two specific areas where the ice and snow assessment can contribute significantly to the structural design. These are sliding or moving snow on slippery sloped surfaces (metal or membrane roofs); and the integrity of the roof drainage path during the winter months.

The first topic has to do with ice and snow accumulations that in the correct meteorological conditions can slide or move, damaging roof projections, mechanical equipment, lighting protection, roof seams, parapet walls and in severe conditions the sliding ice and snow can slide completely from the roof surface damaging property or injuring people below. Circumstances that can lead to a sliding ice and snow scenario can be complex and are not well documented within the industry. This is where an assessment from an experienced ice and snow consultant can prove invaluable, if utilized during initial design rather than in a retrofit condition, which is often the case.

Sliding snow from a roof step on a smooth membrane roof. Photo Credit: Northern Microclimate Inc.

The second topic addresses a key assumption within snow load requirements, that all rain water and melt water from an ice or snow pack on a roof can readily leave the roof surface, therefore eliminating its contribution to the loading condition. However, in complex roof conditions or adverse meteorological conditions, a continuous warm (above freezing) path from source to drain for water flow may not exist. Gutters and roof drains have been known to freeze over with ice formations; alternatively, ice formations (an ice dam) at some location along the drainage path can block large roof areas from draining. Further complicating this issue is the application of heat trace to promote drainage. Often, the addition of heat trace is used to mitigate a potential blockage to the drainage path within gutters, downspouts and on roof surfaces. However, without specific knowledge of the ice and snow formations expected to be experienced, the application of heat trace can be ineffective or in some extreme cases cause problematic or hazardous ice formations. This again is where an assessment from an experienced ice and snow consultant can prove invaluable.

An ice and snow assessment can also help avoid potential issues: at clearstory windows and skylights (maintaining vision or sunlight as well as reducing leakage potential), at mechanical equipment and louvers (reducing snow ingestion or the drifting-in of equipment); and with the placement and size of screen walls and/or parapet walls.

Situating Entrances & Exits

The orientation, layout, or protection of building entrances and exits is also a task where the knowledge gained from an ice and snow assessment can be useful. Questions such as the following can be addressed in a timely and cost effective manner:

- Orientation to prominent winter winds

- Potential for snow infiltration

- Placement and detailing of canopies, wing-walls, wind screens, etc., as effective protection for building entrances and exits

Wind drifted snow cornice at entrance vestibule. Photo Credit: Northern Microclimate Inc.

Building Systems

The choice of building systems can also have an impact on the potential for hazardous ice and snow formations. Modern heating and ventilating systems, in conjunction with improved exterior wall performance, are reducing the reliance on perimeter heating, which in turn can increase the formation of ice and snow on exterior building elements. The overall impact can be a reduction in exterior skin temperature, which is small; however, the resultant increase in volume of ice or snow formation over an entire building skin can create problematic formations.

Planning for Occupancy

As the risk of hazardous ice and snow falling, sliding, or being windblown from a completed building cannot be eliminated under all possible winter conditions, it is therefore beneficial to provide guidelines to the building owner and future operations staff for the creation of operational protocols and winter maintenance plans with respect to ice and snow formations.

Emerging Issues

Energy Efficiency

In an effort to improve the overall energy performance of buildings, the profile of the exterior envelope or façade is changing. An increased use of solar shading devices or double façades has contributed to an increase in falling ice and snow incidents (these elements provide greater surface area for ice and snow to collect). Similarly, an overall increase in façade energy performance (i.e., increased insulation, reduced air leakage and better performing glazing) is contributing to larger ice and snow formations that can be windblown, slide, or fall from a building. Furthermore, the melt and re-freeze of accumulated precipitation on colder exterior surfaces contributes to dangerous icicles or ice sheets that can fall.

Design Trends

Building crowns, wing walls, large mullions, low or no parapets, green roofs, sloped walls and glazing (etc.); all contribute to falling ice and snow. Thus, a review of predicted winter performance of façade details during the design stages of a building is beneficial in identifying and reducing potential falling ice and snow risks.

Material Choices

Slippery roofs and sloped metal or glazed walls can allow ice and snow accumulations to slide and impact building components or areas below the roof or wall, posing a danger to people and property. Currently, there is little guidance available to address moving ice or snow on buildings. However, if the concern is identified during the design of a building and awareness brought to the potential for hazard, solutions can be sought.

Vegetative and cool roof construction techniques can each bring independent challenges to winter design.

The vegetative roof adds roughness and complex geometries potentially increasing the volume of snow collection on the roof surface, as well as increasing the potential for windblown snow transport on the roof surface, creating larger snow drifts in problematic locations. Furthermore, the build-up of soil and planting trays can create challenges with the melt water drainage path, possibly leading to ice formations at un-anticipated locations, creating localized loads. As well, freeze expansion damage to roof materials and flashing details can occur.

Cool roof construction, which is typically made up of increased insulation values combined with light colored roofing materials, has a significant impact on the rate of snow melt. The increased insulation reduces heat loss from the building's interior, while the light colored materials reduce solar absorbance. These two mechanisms can have varying impact on melt water production within an accumulated snow pack depending on the particular exterior weather conditions. However, in its simplest form, the melt out of snow will be slower, making the roof more susceptible to deeper snow, ice, and icicle formations, due to the potential for multiple snow storm events between melting periods. This in turn has implications to snow load assumptions, localized loading due to melt and re-freeze, and the formation of larger ice masses under deep snow formations that can promote sliding ice and snow and/or roof damage due to expansion forces.

New Technologies

Tall buildings can experience frequent wind driven icing at higher elevations. The ice collects in large volumes on parapets, cold walls, antennas, and other structural elements, and then falls. Incidents are rarely reported (publicly); however, they are frequent and increasing due to current design trends and the number of tall buildings. Experienced guidance is required to reduce potential of larger formations.

Relevant Codes and Standards

Building codes and standards have acknowledged the issues surrounding the potential for ice and snow movement on buildings, focusing on aspects of structural design. Some documents have gone further and acknowledge the potential for hazard and damage due to sliding ice and snow formations. However, the existence of procedures, instructions or guidelines that can be implemented to achieve a criteria or standard is not yet available.

Additional Resources

Publications

- Metal Roof Design for Cold Climates, Metal Construction Association.

Published Papers

- "Dam Ice Dam", ASHRAE Journal - Building Sciences 2010 by J. Lstiburek. June 2010.

- "Danger: Falling Snow" by D.A. Taylor. Published in Volume 35 Issue 1 of Canadian Architect, Reprinted in Construction Practice: Selected Applications in Construction Technology Section 2 (NRCC - 35475), 1990.

- "Minimizing the Adverse Effects of Snow and Ice on Roofs", Proceedings of the International Conference on Building Envelope Systems and Technologies (ICBEST-2001) by J. Buska and W. Tobiasson. Ottawa, Canada: 2001.

- "Sliding Snow and Ice on Buildings: a balance of risk cost and aesthetics", Proceedings of Snow Engineering V by C.J. Williams; M. Carter; F. Hochstenbach and T. Lovlin. London, England: Published 2004.

- "Sliding Snow from Sloped Roofs: Its Prediction, Potential Hazard and Mitigation", Proceedings of Snow Engineering VI by N. Isyumov. Whistler, British Columbia, Canada: 2008.

- "Sliding Snow on Sloping Roofs", Canadian Building Digest CBD-228 by D.A. Taylor. Institute for Research in Construction, November 1983.

- Snow and freezing water on roofs, Cold Climate HVAC by A. Nielsen and J. Claesson. Greenland Sisimiut: 2009.

- "Snow, ice and icicles on roofs - physics and risks", 7th Nordic Symposium in Building Physics by A. Nielsen. Reykjavík, Iceland: 2005.

Articles

- "Beware of Falling Ice and Snow: A winter perspective on building design", Construction Canada, Vol. 54, No. 1. by Mike Carter, C.E.T. and Roman Stangl, C.E.T., January 2012.

- "Winter Weather Considerations: Avoiding Ice and Snow Damage During the Winter Months" by William Meyers. Architectural West, March/April 2010.

Websites

- Snow Engineering—Snow and Ice Studies, Alan G. Davenport Wind Engineering Group, Boundary Layer Wind Tunnel Laboratory, University of Western Ontario

- U.S. Army Cold Regions Research and Engineering Laboratory Facilities and Products

Building Enclosure Design Principles and Strategies

Introduction

Within This Page

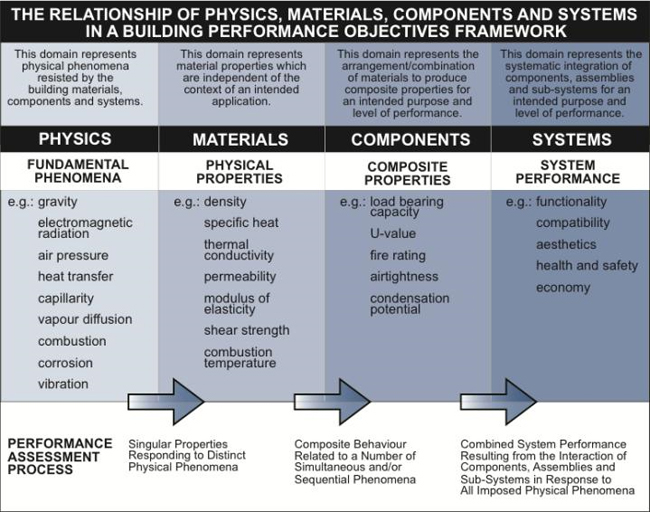

The innovative design of building enclosures relies less on successful past precedents than the application of building science. This is not because there is little to be learned from existing buildings, but is due to the changes in materials and methods that result from building technology innovation. Combined with growing expectations for high performance, building enclosure design is now required to satisfy a large number of performance parameters that were not given a great deal of consideration in the past. Building enclosures were always expected to be durable and provide a degree of environmental separation, but now they must address issues like energy efficiency, daylighting, indoor air quality, fire safety, thermal comfort, and carbon footprint. There is now a need to explicitly ensure these performance objectives are fully satisfied at the design stage.

Performance: the level of service provided by a building material, component or system, in relation to an intended, or expected, threshold or quality.

Performance-based design is not a new idea and in fields like structural engineering, limit states design has been deployed to reliably achieve appropriate levels of performance. There remain a number of challenges to overcome before a similar approach is available for building enclosure design. Until such time, the information that follows is intended to provide a practical framework for applying building science principles and strategies to the design of well performing building enclosures.

Before continuing with this Resource Page, it is highly recommended to review a summary of building science Vocabularyi in order to be consistent with the terminology used throughout the building science series of WBDG Resource Pages.

For those interested in knowledge enrichment, access Historical Development of the Building Enclosure to understand how ideas and technology have evolved.ii

Description

Principles of Enclosure Design

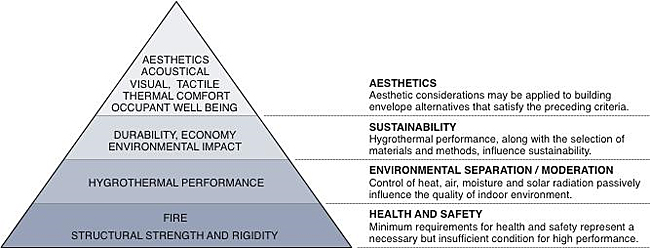

The requirements for wall performance were outlined some half a century ago (Hutcheon 1963)iii, and are applicable to all enclosure systems and components. The major considerations were identified as:

- Strength and rigidity

- Control of heat flow

- Control of air flow

- Control of water vapor flow

- Control of liquid water movement

- Stability and durability of materials

- Fire

- Aesthetic considerations

- Cost

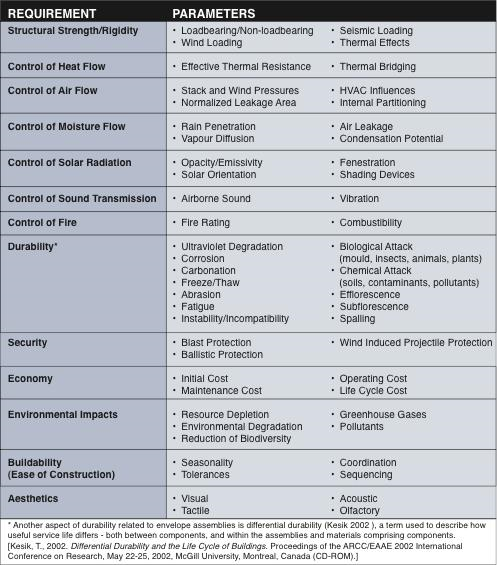

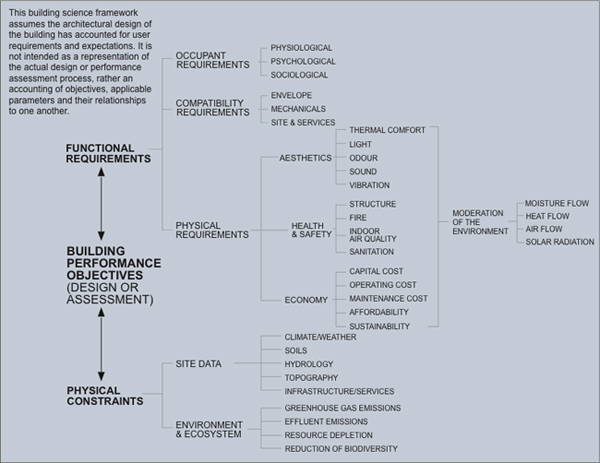

Since Hutcheon's time, additional objectives have been adopted, such as consideration of the environmental impacts associated with building methods and materials, and the need to provide safe and secure buildings. The objectives or requirements for acceptable wall performance were implicit within traditional methods and materials of construction. With the advent of modern building science, these objectives became more explicit in response to technological innovation. Table 1 summarizes contemporary performance requirements and their corresponding assessment parameters.

Table 1. Performance requirements for building enclosures and their corresponding assessment parameters.

Separator Versus Moderator

A critical principle in building science involves the difference between environmental separation versus moderation. For example, the control of fire and smoke movement is understood to be a strategy that attempts to completely separate smoke and fire from the indoor environment. The strategy employs a fire-rated assembly that fully controls the leakage of smoke by virtue of its airtight construction and in some cases, the control of air pressures between compartmentalized spaces.

Moderation involves a strategy where the severity of the difference between the indoor and outdoor environments (or two adjacent indoor environments) is moderated within a tolerable threshold. For example, the control of heat transfer does not seek to reduce the rate of heat transfer to zero, rather to a level that satisfies requirements for comfort, energy efficiency and the control of condensation/wetting. Table 2 summarizes key control strategies for the design of building enclosures, most of which involve a moderation strategy rather than a separator or 'perfect barrier' strategy.

Table 2. Fundamental strategies for the control of heat, air, moisture and solar radiation in the design of building enclosures.

A review of the physical phenomena and corresponding control strategies indicates the control of moisture migration is by far the most important control function to be addressed by the designer. Moisture related problems in buildings are common and broadly vary in types and consequences. A brief listing of moisture related problems illustrates this point: frost heaving, adfreezing, water leakage, wood rot, mold growth, spalling, efflorescence, corrosion, and deterioration and staining of finishes. Consequences range from structural failure to cosmetic flaws, and in some cases the health of the occupants can be adversely affected as in the case of mold growth causing allergic and respiratory problems.

The list of the harmful effects of water in building materials and assemblies is indeed a long one. In many instances the water by itself is not harmful, and only when combined with other phenomena does it cause rapid deterioration. On the other hand, the other phenomena involved will not cause deterioration in the absence of water. It follows then that if water can be controlled a building can be made more durable and the maintenance and repair costs reduced. If this could be achieved only by the use of very expensive materials and construction it could be argued that it is better to let the building deteriorate and to replace the damaged portion from time to time. In fact, however, durable construction can be achieved with relatively inexpensive materials and designs, provided that the designer understands the behavior of water in its various forms and applies the necessary controls to prevent it from accumulating in harmful quantities.iv

Addressing the control of moisture in building enclosure design generally takes precedence over other control measures simply because so many of the requirements for the control of heat transfer, air leakage and solar radiation are satisfied when all forms of moisture management have been carefully considered.

A number of related pages are dedicated to explaining these various control strategies in depth:

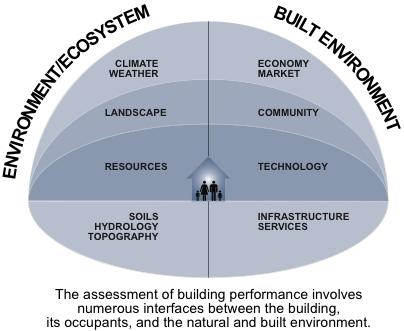

For the purpose of applying building science effectively, it is important to appreciate the building enclosure is the primary environmental separator/moderator. It performs a passive role, unlike mechanical and electrical systems that actively supplement the amount of heat, air, moisture and daylight the enclosure is unable to provide. When all active systems fail, the building enclosure is the last line of defense between the indoors and the outdoors. High-performance building enclosures provide passive survivability during extreme weather phenomena and natural disasters, and safely shelter their inhabitants. The following section outlines a number of critical relationships and factors involved in the design of building enclosures.

Design, Materials, Workmanship

In order to appreciate the approaches involved in building enclosure system design strategies, it is important to understand several key relationships that impact performance.

Workmanship and materials are imperfect. If it is likely for a set of working drawings and specifications to contain errors and omissions, then it is almost a certainty that the translation of these instructions to contractors and their trades will be imperfect. Inaccuracy and inconsistency of workmanship and materials, in conjunction with variable weather conditions, result in buildings that only approximately fulfill their design intent.

Management approaches with respect to physical phenomena affecting the building enclosure system are shown through experience to be superior to barrier approaches. Not only do they provide redundancy of critical control functions, but they are more forgiving to construct, since tolerances are greater than those required by a barrier approach.

Enclosures must adequately control moisture migration, heat transfer, air leakage and solar radiation. Experience indicates that when the requirements for the control of moisture migration have been satisfied, the other control requirements are either simultaneously satisfied, or more easily satisfied than if moisture migration is not addressed at the outset.

In practical terms, these relationships guide designers to assume flawed construction that must be compensated with redundant control measures focused on moisture management. For experienced designers these assumptions are almost axiomatic.

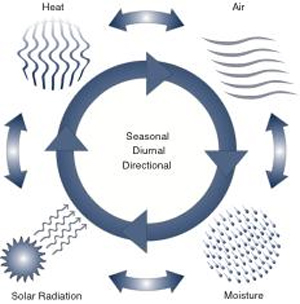

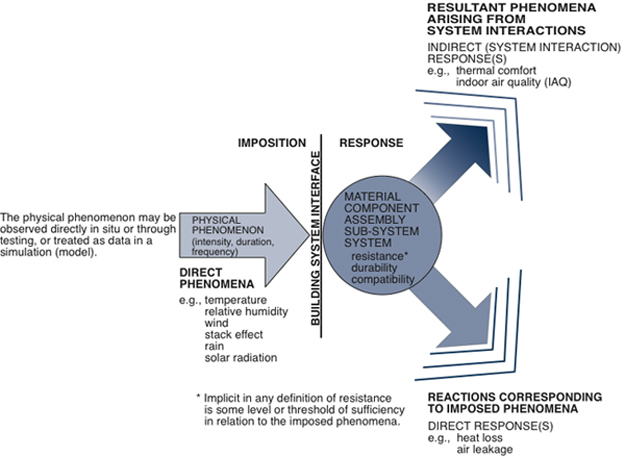

Physical Phenomena

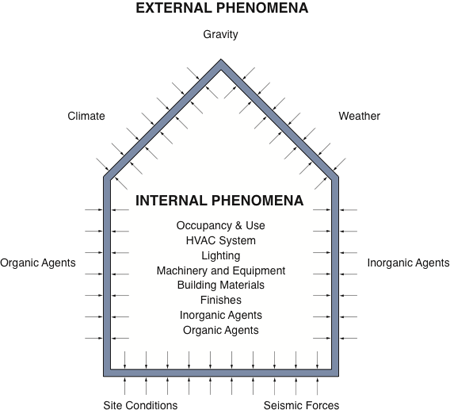

Environmental conditions, both internal and external, establish the physical phenomena that impact the performance of the building enclosure. In order to be durable and provide adequate moderation of the environment, the building enclosure must be designed to provide a threshold of control over, or resistance to, these phenomena.

Figure 1. Imperfect building enclosures must manage all imposed internal and external environmental phenomena.

Intensity, Duration, and Frequency

All physical phenomena share intensity, duration and frequency as defining characteristics. Events such as earthquakes, tornadoes, hurricanes, and to some extent floods, are typically high intensity phenomena of short duration and low frequency. In most climate zones, vapor diffusion, heat transfer, and air leakage are normally low intensity phenomena of relatively long duration and seasonal frequency. Both types of phenomena have accounted for considerable damage to buildings, however, the strategies for dealing with each varies not only in terms of the actual control measures, but mainly according to the associated risks and consequences of failure.

Risk and Consequences

Risk of failure involves the probability of a specified level of performance proving inadequate to resist an imposed physical phenomenon or phenomena. The likelihood of failure must be reconciled with the consequences of failure in terms of safety, health, functionality, economy, and aesthetics. Minimum levels of adequacy for health and safety in buildings have been established through codes and standards, and guide the designer in these vital aspects of building performance. However, the risks and consequences of failure for a building requirement such as structural integrity are much better understood than for moisture protection. For this reason, many building enclosure design strategies are based less on probability and analytical models, and more on precedent, heuristics, and common sense. This does not suggest that analysis is completely abandoned, but instead acknowledges that the results are often only accurate to within one order of magnitude. Numerical data must be interpreted qualitatively, requiring significant experience and judgment on the part of the designer.

Durability and Redundancy

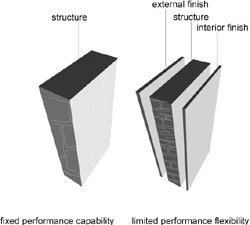

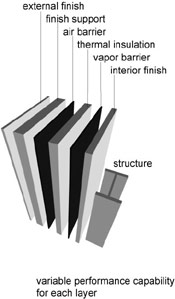

Durability is a key consideration in effective enclosure design and this requires that a level of redundancy be provided in terms of critical control functions for moisture, heat, air leakage, and solar radiation. [Resilience is a concept related to durability that applies to the design, construction, and operation of buildings and infrastructure that are resistant to natural and man-made disasters.v]

Redundancy—An enclosure with more than one 'line of defense' against imposed phenomena may be redundant with respect to one or more critical control functions. The degree of redundancy may range from: (i) resistance to each imposed phenomenon is distributed across all materials in the assembly (fully redundant); to (ii) resistance to each imposed phenomenon correspondingly addressed by individual materials within the assembly (non-redundant, hence each material represents a 'perfect barrier'). To be cost-effective and practical, redundancy is not simply doubling up on every control layer, or only selecting materials that address all of the control functions simultaneously. Control layers may be selected so as to perform more than one control function, or to significantly contribute to enhancing the performance of one or more control layers.

Multi-Functionality—A material may be uni-functional, such as a structural element, or it may address more than one required control function resisting imposed physical phenomena. Multi-functionality may be described as either: (i) single material addresses all enclosure control functions; or (ii) material primarily addresses one control function (first line of defense) and contributes to another control function(s), (second line of defense). For example, exterior insulating sheathing can act as a thermal control layer while contributing to air leakage and rain penetration control. If it is a vapor resistant material, such as extruded polystyrene, the exterior insulating sheathing can also resist vapor diffusion.

Contribution—A material may improve or enhance the performance of another material or assembly of materials without displaying multi-functionality or explicitly adding to redundancy. For example, an air barrier membrane may reduce air movement through an air-permeable insulation material, improving its thermal effectiveness but not contributing to the nominal thermal resistance of the assembly.

High-performance building enclosures provide high levels of resistance to imposed phenomena by intelligently arranging materials that are multifunctional with respect to critical control functions and contribute to the enhanced performance of one or more materials comprising the assembly.

Continuity

The continuity of critical control functions is among the most significant considerations when detailing building enclosures. Air and water leaks along with thermal bridges not only compromise performance but often lead to severe degradation of the building enclosure. In extreme cases, problems such as mold arise from a failure to maintain continuity of critical control functions. There are four Resource Pages that address building enclosure transitions to maintain continuity: Integrating the Building Enclosure; Wall to Roof Transitions; Wall to Window Transitions; and Wall to Foundation Transitions. For the purposes of enclosure design principles and strategies, it is extremely important to observe the need to achieve continuity of critical control functions, especially at transitions between enclosure assemblies.

Buildability and Economy

Lines on working drawings are straight, and the dimensions are precise, but in the field the building artifact is always an approximation, sometimes too crude an approximation to perform adequately. How does this come about?

Contractors and their trades are highly constrained by time and budget on virtually all construction projects. They are generally not inclined to spend more effort on construction than it is economically worth. If the successful (usually lowest) bidder on a construction project discovers that an assembly or detail is too expensive to execute properly, then ad hoc modifications (a.k.a. cutting corners) may be implemented by workers intent on meeting productivity quotas.

In some cases, the skill levels of the trades may be too low for the work they have been awarded. In other cases, the knowledge and experience of those performing quality assurance and supervision are simply not up to par. When none of the above factors come into play, other problems such as substandard materials or bad weather affect the quality of the finished product. Unforeseen site conditions, usually involving soils and groundwater, may compound the situation further, along with human factors such as labor disputes (strikes).

For these reasons, practical considerations in design should not be underestimated. Forgiving building systems that accept the reality of imperfect materials, workmanship, site conditions, and human factors are truly elegant and sustainable design solutions. Details whose proper execution demands the most efficient and least expensive methods are the real masterpieces of building enclosure design. This approach is certainly preferable to being 50% over budget on a project with a leaky roof, especially from the perspective of the building owner.

The economy of a building enclosure, in particular its initial capital cost, is largely determined by buildability, which also impacts its life-cycle economy if assembly of the enclosure exceeds the capability of the work force. Bad details lead to bad workmanship and ultimately poor performance.

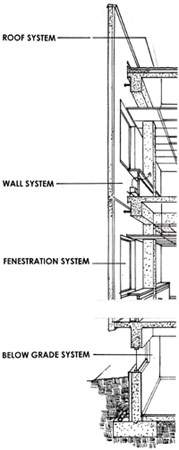

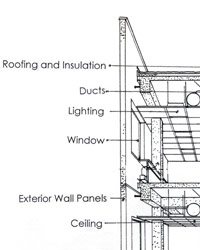

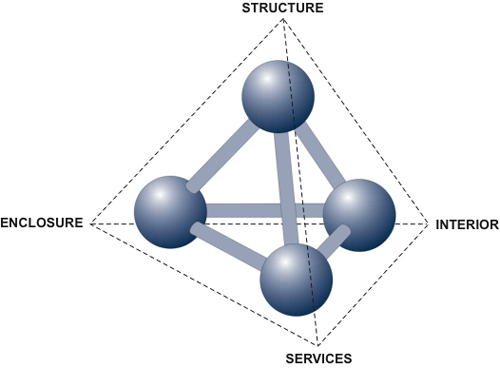

Building Enclosure System Integration

The architectural design of building enclosures, foundations, walls, roofs, windows, and doors demands functional integration and aesthetic orchestration. Assuming that each of these assemblies and components has been individually resolved, it must be recognized that a second order of design/assessment is subsequently required. This ensures that the major assemblies and components are compatible, both mechanically at their connections and intersections, and in terms of their collective contribution towards the management of critical control functions. This iterative process from architectural concept, through physics, materials, and components, and back to the building as a system is a cornerstone of modern building science and its contribution to architectural design practice. Keeping these principles and key relationships in mind, the next section examines the critical physical phenomena that need to be considered in the design of effective building enclosures.

Climate, Exposure, Occupancy, and Building Energy Profile

Designing an effective building enclosure must properly consider the following factors:

- Climatic zone where the building is located

- Annual exposure to precipitation

- Intended use or occupancy of the building (interior climate class), and

- Building energy profile (skin-load versus internal-load dominated).

Based on these factors, it is possible to design building enclosures that adequately address all of the imposed physical phenomena while delivery high performance.

Climate Zones (Hygrothermal Region)

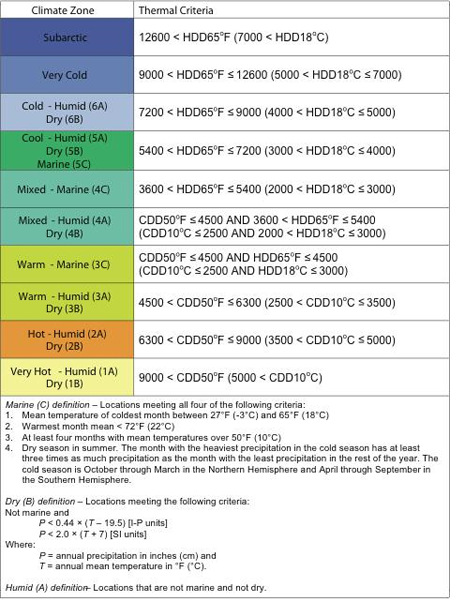

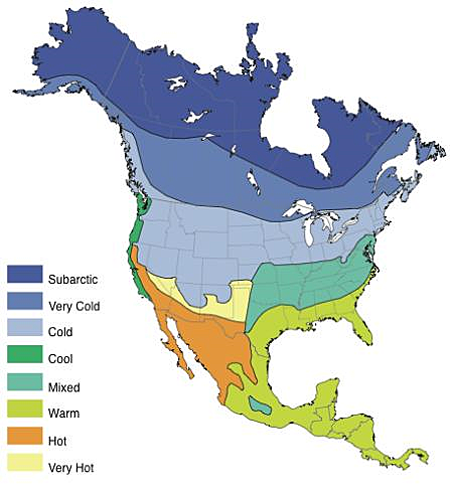

ASHRAE has defined 8 basic climate zones, some with variations, as listed in Table 3.

Table 3. ASHRAE climate zone definitions used for the design of hygrothermal control functions in building enclosures.

Climate zones influence the selection and arrangement of hygrothermal control layers in a building enclosure. The appropriate levels of thermal resistance may also be derived from the zone thermal criteria. Figure 2 depicts the hygrothermal climate zones of North America.

Figure 2. The selection and arrangement of heat and moisture (hygrothermal) control layers is based on climate zones. North America has all 8 climate zones and this broad range of climates explains why enclosures that are effective in one climate zone fail to perform properly in other climate zones.

Another way to understand climate zones is in terms of wetting and drying potential. All of the humid and marine climate zone variations in Table 3 have a high wetting potential and a low drying potential. This means that if the building enclosure experiences wetting due to moisture migration from either the exterior and/or interior, it will likely not dry out fully and be susceptible to mold and decay. Mixed, warm, hot, and very hot climate zones that are humid or marine will predominantly experience vapor migration across the building enclosure from the exterior toward the interior, while the cool, cold, very cold and subarctic zones will experience vapor flow from the interior to the exterior. The practical implications of these phenomena are presented in Understanding Air and Vapor Control Layers.

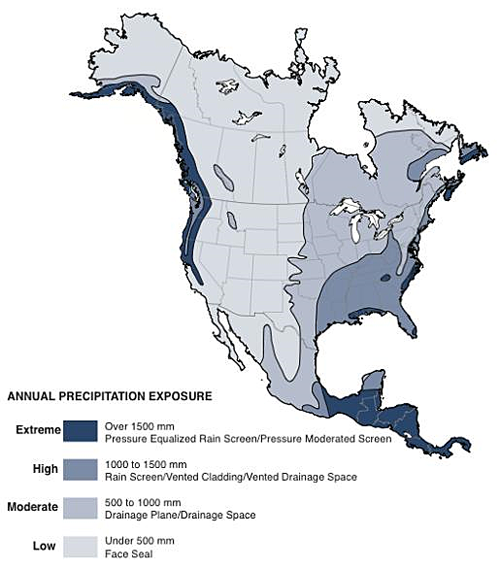

Precipitation Exposure

The annual quantity of precipitation is an indicator of the wetting potential of a particular geographic location, and also informs the selection of an appropriate cladding system that can adequately manage the amount of rainfall exposure.

Figure 3. Annual precipitation exposure is a critical factor in the selection of a suitable cladding system that can provide adequate moisture protection.

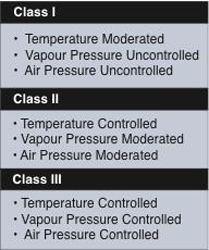

Indoor Climate Class

Table 4. Indoor climate classes based on a qualitative index advanced by Lstiburek 2002.vi

The building enclosure must also withstand environmental loads based on the interior building conditions. Table 4 outlines indoor climate classes based on temperature, vapor, and air pressure regimes. It should not be confused with ISO Standard 13788 characterization of indoor climate classes. Instead, it should be employed as a guide to the level of moderation or separation that must be achieved by the control layers. For example, a warehouse for storing non-perishable goods may be temperature moderated by a heating system set to prevent freezing but with no intentional means of controlling humidity or air leakage. As such, there will not be large gradients across the building enclosure and only minimal control layers will be required. On the other hand, in a facility where temperature, vapor, and air pressure must all be carefully controlled, such as a pharmaceutical laboratory, it will be essential to provide high quality control layers to provide adequate resistance across the full range of differential gradients that must be maintained within a relatively narrow tolerance.

It is important to note that the higher the climate class, the more environmental stress will be placed on the control layers. Not only do the materials comprising the control layers have to be properly specified, but their detailing to ensure continuity must also be carefully devised. In the past, building designers relied on the power of HVAC systems to manage indoor environmental conditions, but since the time of the first energy crisis in the early 1970s, there has been a steady move away from active systems of environmental control in favor of passive systems, primarily the building enclosure.

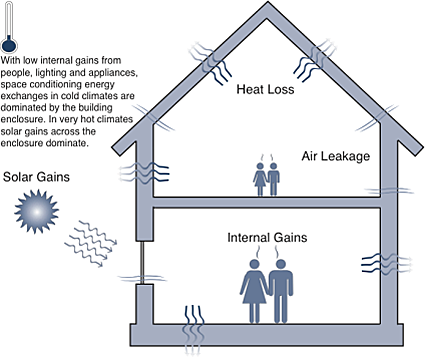

Building Energy Profile

From an energy efficiency and thermal comfort perspective, buildings are often classified according to the primary drivers for space conditioning loads. This translates into two major profiles of buildings: skin-load dominated; and internal load dominated. The design of the building enclosure must account for these characteristics to provide energy efficient operation and deliver thermal and visual comfort to the occupants.

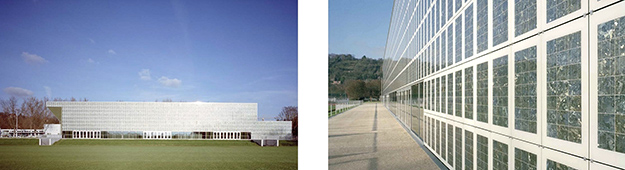

Skin-Load Dominated Buildings

A skin-load dominated building has the largest proportion of space conditioning energy loads determined by the building enclosure. This type of building is characterized by a relatively low occupant density where internal heat generation is minimal (e.g., housing), and natural ventilation and daylighting may be easily accomplished. They are also located in a climate that is either cold or colder, or hot or hotter. Mild climates do not exert a significant temperature differential over a sufficient duration to render buildings skin-load dominated. This building type relies on high-performance windows set in a thermally efficient enclosure with minimal air leakage and thermal bridging. In general, skin-load dominated buildings benefit from passive solar heating strategies in cold climates and solar shading and natural ventilation strategies in hot climates. Typical skin-load dominated buildings include houses, apartment buildings, small commercial and institutional buildings.

Figure 4. Skin-load dominated buildings benefit the most from high-performance building enclosures, and can take the best advantage of passive control strategies.

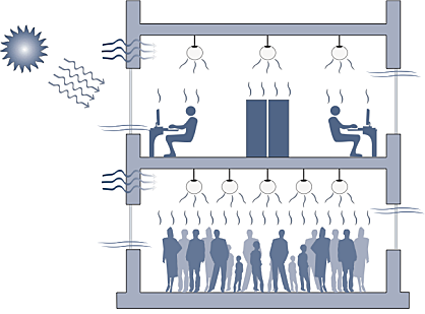

Internal-Load Dominated Buildings

Buildings that have high occupant densities and high internal gains from lighting and/or equipment are considered internal-load dominated buildings. Sometimes these are also referred to as a core-load dominated building. Regardless of climate type, the internal heat generation puts high demands on ventilation and cooling that are further driven by solar gains. For this building type, efficient means of rejecting excess heat generation translate into building enclosures that are typically less thermally efficient than effective at reducing solar gains by deploying shading devices and selecting appropriate optical properties of glazing. Different fenestration and shading strategies can also be deployed corresponding to the solar orientation of each face of the facade. Office towers and large retail facilities like shopping malls are notable examples of internal-load dominated buildings. Integration of the building enclosure with the HVAC systems is critical for achieving high performance in these types of buildings.

Figure 5. The energy performance of internal-load dominated buildings is strongly influenced by the window-to-wall ratio, effective U-value and solar heat gain coefficient of the glazing, and the airtightness of the building enclosure. Heat recovery for ventilation air and lighting system efficiency are the two most critical considerations for active building systems in these types of buildings.

There are also hybrid building types based on their changing occupancy. Schools are an example of buildings that are internal-load dominated when the classes are full during the day, and skin-load dominated on evenings and weekends when they are unoccupied.

It is important to appreciate that the hygrothermal design of a building enclosure to properly manage moisture, heat, and air flow is a function of the climate zone, precipitation exposure and indoor climate class. The building energy profile type is taken into consideration for the optimal levels of thermal insulation and selecting strategies for daylighting, passive solar heating, shading devices and passive cooling (natural ventilation).

Building Enclosure Design Strategies

Design strategies for building enclosures are a relatively recent opportunity for building designers. In the past, locally available materials and successful past precedents guided a highly traditional building industry where certain types of performance problems, (i.e., energy efficiency, thermal comfort, etc.), were considered acceptable. Today, a multitude of performance requirements must be satisfied amid a marketplace of innovative materials, components, and systems the designer is responsible to fully integrate, and the constructor must properly deliver. Picking a suitable generic building enclosure typology is an important first step.

Building Enclosure Typologies

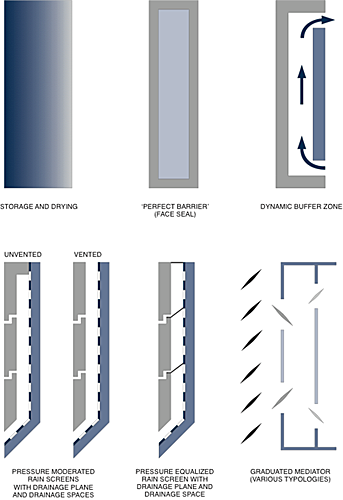

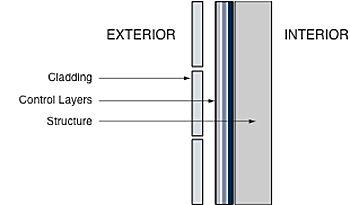

The discussion that follows is focused on exterior walls recognizing that many of the considerations also apply to roofs and below-grade assemblies. It is interesting to note from Figure 6. that after thousands of years of building construction by humans, only a handful of building enclosure typologies have emerged. Most of these evolved by trial and error with some recent innovations arising from the application of building science principles, especially as it relates to rain penetration control.vii

Figure 6. Schematic representations of basic building wall enclosure typologies.

Storage and Drying

Traditional masonry buildings relied on the storage and drying strategy for the management of moisture on a seasonal basis. The monolithic masonry façade was not only part of a load-bearing system, but also a hygric buffer with a capacity to store large quantities of water during wet periods, which are then released during dry periods. As long as the hygric buffer capacity was sufficient to store moisture accumulations, and the flow of moisture was not impeded at either the interior or exterior of the wall, this enclosure system would render good service. Some drawbacks of this strategy are the large quantities of materials and labor needed to erect the enclosure, the poor thermal efficiency due to a lack of insulation, and the absence of an air barrier system. Durability and moisture management are achieved at the expense of energy and thermal comfort. It is important to note that by abandoning this approach in favor of high performance, critical considerations have increased while margins of error have decreased.viii

Perfect Barrier

Modern building science experience has demonstrated that perfect barrier or "face seal" strategies for building enclosures do not have a high likelihood of acceptable performance, except for highly arid climate zones. The imperfect nature of materials and workmanship results in a high probability the perfect barrier will have discontinuities, either at the time of construction / assembly and/or after exposure to the elements. Maintaining a perfect barrier is a costly and perpetual proposition. Perfect barrier or face seal systems do not have any redundancy of critical control functions, have no provisions for draining unintentional water penetration, and should therefore be avoided in high-performance building design. Perfect barriers or face seal systems rely on tightly sealed joints using caulking and/or gaskets to resist water and air leakage. This approach has been applied to components such as windows and doors that are manufactured under controlled conditions in factories. The joint between the component (window) and the opening in the enclosure is also highly dependent on workmanship and material durability.

Dynamic Buffer Zone

The dynamic buffer zone is a strategy employed in the preservation of historic buildings where the exterior facade cannot be altered, but typically cooling is being provided through a modernized HVAC system. This is exclusively an enclosure retrofit strategy intended to create a buffer zone inboard of the existing facade, which continues to reside in its original hygrothermal environment.

Graduated Mediators

The most notable contemporary example of a graduated mediator is the double-skin facade (DSF), but there are many historical precedents where a system of overhangs, screens, and louvers manipulated insulation, shading, and natural ventilation to enhance environmental control. This strategy is usually associated with mild climates where the potential passive contribution of the enclosure is significant. In more extreme climates, a single enclosure assembly is generally preferred as this enables multiple lines of defense (in effect a compressed graduated mediator) to be incorporated cost-effectively into a more conventional building enclosure.

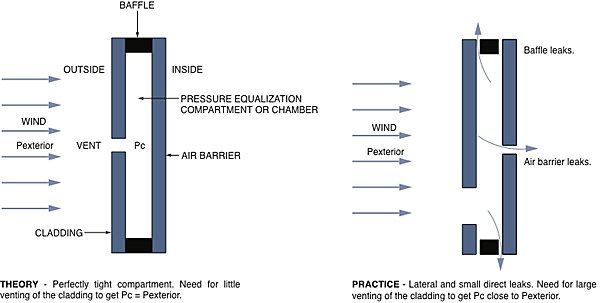

Pressure Moderated Drainscreens