Air Traffic Control Tower and Radar Approach Control Facility Design Guide

<p>Replaced by: <a href="/dod/ufc/ufc-4-133-01" target="_blank">UFC 4-133-01</a></p>

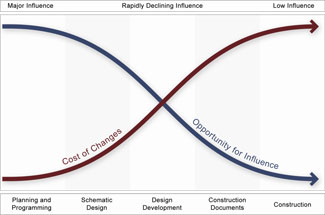

This Design Guide provides basic guidance and criteria to programmers, planners, architects, engineers, design and construction agents, commanders, and construction contractors for the programming, design, and construction or renovation of Air Traffic Control Towers (ATCT). Specific items herein are minimum standards, and may be modified by particular requirements of the base or other special design parameters. For latest information and drawings, plans, utility, siting and electronic requirements, consult the Air Force Flight Standards Agency (AFFSA).

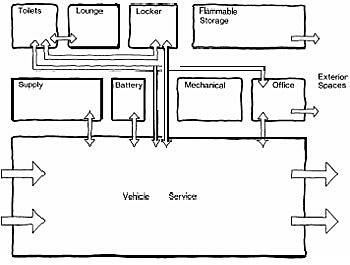

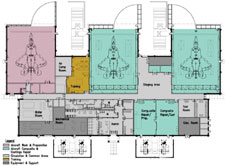

Aircraft Industrial Support Facilities Design Guide (AMC)

This design guide provides the basic criteria to organize, evaluate, plan, program, and design Air Mobility Command (AMC) Aircraft Industrial Support Facilities (AISF). It applies to the design of all new construction and renovation projects. The information presented is intended to make commanders and their staff aware of important design considerations and to aid them in project development. Quality facilities will improve the maintenance specialists efficiency and ability to service and repair equipment and encourage pride of ownership in their work space.

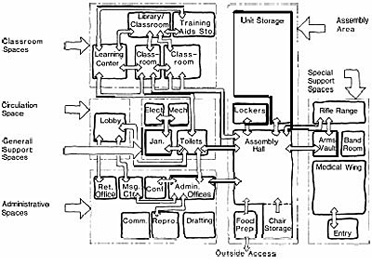

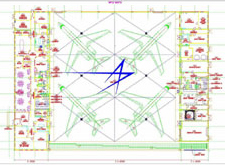

Aircraft Maintenance Training Facility Design Guide (AMC)

This guide provides the basic criteria to evaluate, plan, program, and design maintenance training facilities to house all AMC maintenance training functions, including AETC resources. It is intended to ensure personnel are aware of important design considerations and to aid in project development.

Airman Leadership School Design Guide (AMC)

This design guide provides the basic criteria to organize, evaluate, plan, program, and design Air Mobility Command (AMC) Airman Leadership School (ALS) facilities.

Alternative Energy

Introduction

Within This Page

While the large majority of energy used in the United States still comes from fossil fuels (see EIA for example), there is also tremendous growth in alternative and renewable energy technologies. In this context, alternative energy refers to energy not derived from traditional fossil fuel sources (coal, natural gas, petroleum) through conventional processes. Renewable energy is a subset of alternative energy; according to the National Renewable Energy Laboratory (NREL), "Renewable energy resources—such as wind and solar energy-are constantly replenished and will never run out."

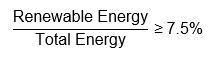

Both market and regulatory forces are driving increased adoption of renewable energy. The Energy Policy Act of 2005 (EPACT), for example, calls for federal agencies to obtain at least 7.5% of their electricity from renewable sources. To stimulate development of new renewable energy projects, Executive Order 13693 requires federal agencies to explore on-site renewable energy generation at their facilities. Many states around the nation have implemented renewable portfolio standards (RPS) mandating a minimum fraction of renewably generated energy in all electricity sold. The Database of State Incentives for Renewables and Efficiency (DSIRE) has information on some of these RPS's.

In conjunction with regulatory requirements for renewable energy, costs of fossil fuels remain rather high and costs of some renewable and alternative energy technologies are coming down. This article focuses on several such energy sources, with a primary focus on electricity generation. The practical use of these systems varies with the specific technology, application, location, cost of energy, and other factors. While many of the technologies are becoming more cost-effective, alternative energy generation is not a substitute for reliable energy efficiency strategies. Implementing efficiency strategies first is still the best approach to meet most energy goals.

Description

Wind

For centuries, people have harnessed energy in the wind—historically this has been used as mechanical energy for milling or water pumping. Wind-powered water pumps are still used in remote areas of the U.S., but harnessing the wind to generate electric energy has become much more common. In modern wind turbines, kinetic energy in the wind is converted to rotational energy and then to electrical energy. This electricity is then conditioned and—in most cases—sent into the utility grid.

In some parts of the country, wind energy has become cost-competitive with conventional sources of electricity generation. There are a growing number of wind generators available with capacities ranging from a few hundred watts (powering small off-grid homes, sailboats, etc.) to several megawatts (for utility-scale generation). The physical size of these generators has a similar range&mdsh;diameters from 3–4 feet to 300–400 feet.

Wind generators are certainly most effective in areas with consistent, high-speed winds. Trees, buildings, and topography can slow winds down tremendously. In the United States, the best wind resources are generally near the coasts (off-shore) or on the Plains. DOE, NREL, and others have developed wind resource maps for the country and some states have developed more detailed maps.

Proper location of wind turbines is critical. Because there can be wide variations in wind speed over small distances, best practices often call for monitoring wind resources at a site (or several potential sites) for a year or more. With smaller generators (several kilowatts), turbines should typically be mounted 30–50 feet above the next highest object in a 500-foot radius (trees, buildings, etc). Larger generators are centered 100 feet or more off the ground where wind speeds are higher and less turbulent.

Because most electric energy is used in buildings, many people have explored mounting wind turbines on top of buildings. This is often not a viable strategy because of the weight, vibrations, torque, and noise of the generators. To get access to higher wind speeds, generators should be positioned well above nearby buildings. There are some wind generator products, however, specifically designed for mounting on buildings. They are usually small (typically 2000 Watts or less) and are still subject to wind speed and turbulence limitations.

Wind turbines mounted on an apartment building in the Bronx, New York Photo credit: Steven Winter Associates, Inc.

A wind turbine at a Massachusetts school Photo Credit: Northern Power Systems

While small, building-mounted turbines can be appealing to designers, larger turbines (located far above buildings and other obstructions) are much more effective with respect to electricity generation.

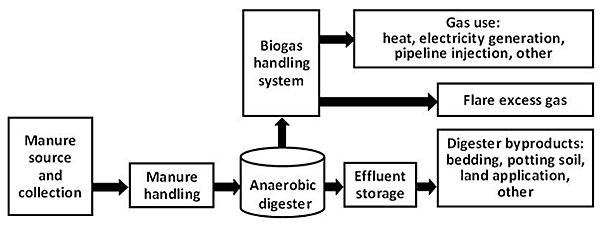

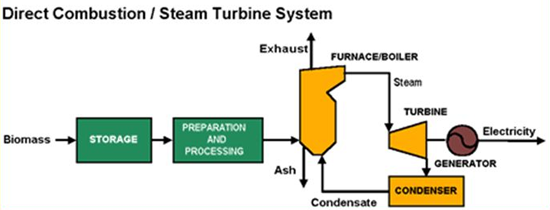

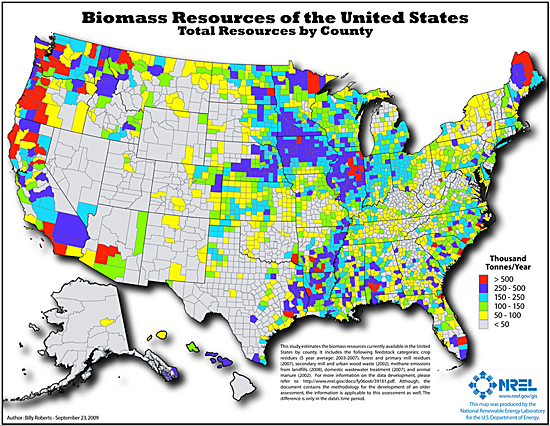

Biomass

Biomass power generation typically refers to the combustion of plant material to power turbines which—in turn—generate electricity. The term biofuel generally refers to a fuel derived from plant material (biomass) that can be used in lieu of conventional fossil fuels.

An efficient wood stove in a new home Photo Credit: Steven Winter Associates, Inc.

The oldest use of biomass energy is burning wood to keep warm. This is still quite common in homes today, and there are also more advanced boiler systems that burn wood to heat water for use in homes or larger buildings. Some of these devices are designed to burn wood pellets rather than larger pieces of wood. Wood pellets are small (less than one inch) pieces of processed biomass from a variety of sources (wood chips, sawdust, waste from wood processing, etc.) Pellet-burning appliances typically have hoppers that feed the fuel to the firebox at a controlled rate—making pellet burning easier to control than some other types of biomass appliances. More information on this and other wood burning technologies for buildings is available through ENERGY.GOV Energy Saver pages.

On larger scales, many timber and agricultural industries burn wood and agricultural waste to obtain useful heat—the heat can be used directly or used to power turbines to generate electricity. When the biomass fuel is inexpensive—especially when it is a waste product—such power generation can be very cost-effective.

As with burning of fossil fuels, burning biomass releases carbon dioxide and other pollutants. Because the carbon in biomass has quite recently been absorbed from the atmosphere, if the biomass resource is managed sustainably there may be little net-emissions of carbon dioxide. This closed carbon cycle, however, does not necessarily include any energy needed to cultivate, harvest, and process the biomass. In addition to pollutants, opponents of biomass generation cite potential effects on regional agriculture or forestry. With growing demand for biomass, there may be pressure to harvest resources in less sustainable ways.

Biofuels

Fuel pump with 20% biodiesel (B20), 85% ethanol, and standard unleaded fuel with 10% ethanol. Photo Credit: Charles Bensinger and Renewable Energy Partners of New Mexico

As described above, biofuels are fuels derived from biomass that can be used in place of conventional fossil fuels. The two most common biofuels are ethanol and biodiesel. Ethanol is currently used in gasoline mixtures to power many automobiles. Most of this ethanol comes from the fermentation of sugars found in food crops, primarily corn. Federal incentives make this cost-effective, but there is growing concern that using ethanol derived from fermentation of corn sugars is not sustainable; there may be more energy needed to cultivate, harvest, and process the material than is contained in the final fuel produced. Other ethanol production strategies—using cellulosic material rather than sugars—can derive ethanol from wood chips, leaves, agricultural waste, and similar material. These show promise with respect to sustainability, but they currently have substantially higher costs (see EERE Newsletter for more information).

Biodiesel is made by converting natural oils—usually vegetable oils—into usable fuels. The fuel can be used in many engines or combustion appliances designed for diesel or no. 2 fuel oil. The appliances typically need no or minor adjustments, though sometimes a blend of biodiesel and petroleum results in best operation. The manufacturing process is well understood and quite environmentally benign. The chief limitation of biodiesel manufacture is a cost-effective, sustainable source of vegetable oils.

Waste oils were one of the first targets for biodiesel manufacturers. In some areas, restaurant managers—who used to pay substantial fees to dispose of waste cooking oils—found new consumers who were willing to take waste oil at no charge, or even to pay for the used oil. While truly sustainable, such waste oil results in a very small volume of biodiesel. Most fuel is generated from virgin vegetable oils, especially oils from soy or rapeseed. Most experts agree that biodiesel manufacture is much less energy-intensive than conventional ethanol production—i.e. much less energy is used to create the fuel than is contained in the final fuel product.

Solar Energy

Solar energy systems in buildings include systems that capture heat (such as solar water heating systems and passive heating), and systems that convert solar energy into electricity. The latter is done primarily through photovoltaic (PV) systems. PV technology has seen dramatic improvements—and cost reductions—since its first applications in the space program in the 1960's. While the technology is still not inexpensive, from 2006 to 2010, installed costs of PV systems have dropped 30–40%. This drop—combined with higher energy costs, government and/or utility incentives, and time-of-use electric rates—have made PV cost-effective in a growing number of applications.

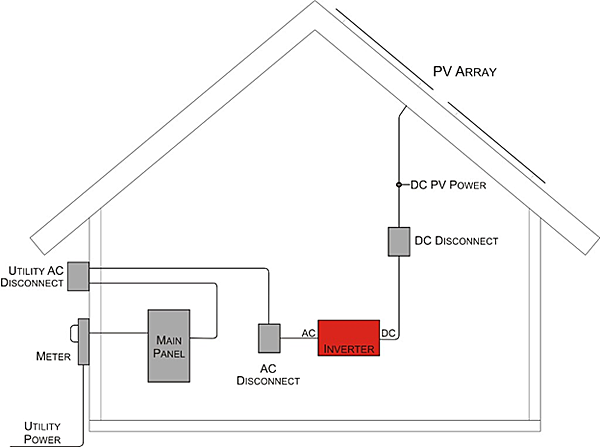

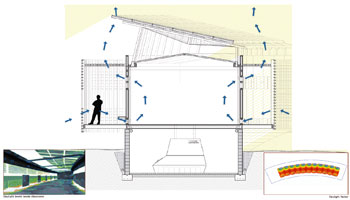

The heart of PV technology is in the semi-conductors (mostly silicon-based) used in the PV modules themselves. The modules convert sunlight to direct current (DC) energy; the DC energy is typically then converted to alternating current (AC) energy via inverters. From the inverters, energy is typically fed into a building's electric system or exported to the utility grid.

Simple schematic showing the main components of a PV system and how it is typically incorporated into a building—in this case a home.

The amount of electricity that a PV system generates depends upon the amount of sun received and many other installation parameters (tilt, orientation, shading, etc.). A simple and accurate tool for predicting generation is PVWatts, developed by NREL.

As PV collectors need direct sun, they are often mounted on roofs. While not extremely heavy, structural factors must be taken into account in planning a roof-top installation. Designers need to be aware of mounting requirements, ballast, and wind loads. Any roof penetrations (for mounting or electrical) need to be planned for and detailed properly. Panels should face south (in the northern hemisphere) and shade (from trees, other buildings, roof-top equipment, etc.) should be minimized. In some cases, PV collectors can be incorporated as part of the roof or building envelope; see the Building-Integrated Photovoltaics page for more information.

While most PV collectors are mounted in stationary positions, some free-standing arrays use devices to track the path of the sun across the sky. This can increase electricity generation substantially (20% or more), but it also adds cost and complexity to the system. PV modules themselves are very durable and have no moving parts; most warrantees are 20–30 years. Inverters are usually shorter-lived; these warrantees are typically 5–10 years.

PV system on a mail processing center in Los Angeles. PVs are one of the most reliable renewable energy technologies, and building integration can be straightforward. Photo Credit: Bill Golove

PVs can also be mounted on the ground or auxiliary structures. These collectors provide shade for parked cars at MCAS Miramar. Photo Credit: MCAS Miramar

Geothermal

Temperatures at the bottom of the Earth's crust—some 5–40 miles below the surface—are typically over 1000°F. In a few locations, these high temperatures reach closer to the surface resulting in volcanic activity, hot springs, geysers, and the opportunity for geothermal electricity generation. Geothermal plants tap relatively shallow pockets of steam; the steam is used to operate turbines that generate electricity.

Clearly, geothermal generation is very location dependent. According to Department of Energy sources, there is approximately 3,000 MW of geothermal electricity generation capacity in the United States. Researchers say, however, that there is potential for 100,000 MW of generation using the latest technologies. At some locations where the accessible geothermal resources are not at sufficient temperature to generate electricity cost-effectively, the heat can be used directly (for industrial processes, space heating, etc.) In the United States, nearly all generators—and most potential sites—are located in the western part of the country (see map).

The term "geothermal" is also sometimes used to refer to ground source heat pumps (GSHPs). While not a means of generating renewable energy, GSHPs can be part of an efficient HVAC system.

Cogeneration

When a fuel—fossil-based or otherwise—is converted to electricity, there is also a substantial amount of heat generated. Usually the quantity of heat generated is far greater than the quantity of useful electricity; typically 30–40% of energy in a fossil fuel is converted to electricity using conventional technologies. Cogeneration or combined heat and power (CHP) is a strategy whereby both useful heat and electricity are obtained from processing a fuel.

These cogeneration units provide electricity to meet some of the base load in a New York City apartment building. While the up-front and maintenance costs are significant, the cost of the natural gas used to generate electricity is less than the cost of electricity purchased from the utility. The thermal energy the engines provide—used for water heating—results in additional natural gas savings of over $10,000 per year. Photo Credit: Steven Winter Associates, Inc.

The concept itself is not new. For nearly as long as people have been burning fuel to generate electricity, people have been looking for ways to utilize the excess heat generated. Newer technologies, combined with higher energy rates, allow smaller-scale, distributed cogeneration to be more cost effective in some buildings or campuses.

Cogeneration is a strategy that includes many types of distributed generation technologies such as turbines, micro-turbines, reciprocating engines, and fuel cells. The most common fuel for these cogeneration technologies is natural gas. A great deal of ongoing research and development focuses on hydrogen fuel cells, but most hydrogen is also currently derived from natural gas. While cogeneration can be considered an alternative energy technology, it is not renewable when it relies on fossil fuels.

Cogeneration is most effective where both electrical and thermal loads are predictable, steady, and coincident. For example, thermal demands for space heating in the winter and electrical demands for space cooling in the summer are not a good match for cogeneration. At the same site, however, there may be steady, year-round thermal loads (e.g. service water) and baseline electrical loads (lighting, equipment, HVAC base loads, etc.). It is possible that a properly sized cogeneration system could cost-effectively meet the base loads while additional heat and electricity would be obtained at lower cost from conventional sources. An accurate knowledge of load patterns—both thermal and electric—is key in designing a good cogeneration system.

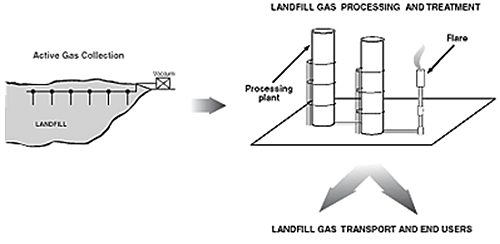

Hydropower

Hydropower is one of the oldest and most prevalent renewable energy technologies, accounting for over 10% of all U.S. electricity in 1996 (EIA). By 2009, however, this fraction dropped to below 7%. Hydropower generation itself dropped 22% over this period. While certainly renewable, conventional hydropower is often not sustainable. The effects of dams on river ecologies are frequently dramatic, and working dams have been removed in an attempt to restore riparian ecosystems.

A beta hydrokinetic generator to be installed near Eastport, ME—location of some of the largest tides in the U.S. Photo Credit: Ocean Renewable Power Company

While it is possible to create sustainable hydropower systems in rivers, these systems tend to be smaller (see EERE resources for more information). Hydropower generation is also moving away from dams towards hydrokinetic systems—systems that use the natural flow of water rather than damming or diverting flow through conventional turbines. There are many types of emerging hydrokinetic technologies; some are designed for rivers, some for ocean areas with strong tidal flows, and some designed to harness energy in ocean waves.

Application

While many alternative energy technologies are becoming more viable and affordable, renewable energy is still often much more expensive than energy efficiency; it is usually much less expensive to save energy than to generate renewable energy. The most cost-effective route to meet the EPAct (or other) renewable energy goals will likely include both increasing the numerator (renewable energy) as well as decreasing the denominator (total energy) in the renewable energy fraction equation:

Understanding total energy use at a facility is also important when exploring appropriate alternative energy systems. Cogeneration systems, for example, should be sized to meet consistent electrical and thermal loads in order to be practical and cost-effective. If power used for space cooling represents a large expense, a PV system sized to reduce this peak can translate into more significant cost savings.

During planning of alternative generation systems, it is critical to consider integration into existing electrical systems and/or the utility grid. Requirements for utility interconnection vary state-by-state and often utility-by-utility. Links to several state regulations can be found at DSIRE; check with local utilities and/or regional authorities for specific permitting and interconnection requirements.

Site considerations are also important during planning. In addition to the obvious (e.g. PV systems should not be shaded, wind turbines should have access to consistent winds), designers should consider aesthetic and noise impacts of the technologies.

Finally, in planning for alternative energy systems, consider ongoing operation and maintenance requirements. O&M requirements for these technologies vary widely. In addition to the costs, make sure the facility or staff has the resources needed to keep the systems operating at peak performance.

Relevant Codes and Standards

- Biodiesel Handling and Use Guide

- Energy Policy Act of 2005 (EPACT)

- Executive Order 13693, "Planning for Federal Sustainability in the Next Decade"

- NFPA 70 National Electric Code®

- North American Board of Certified Energy Practitioners

Additional Resources

Organizations

- American Wind Energy Association

- Geothermal Energy Association

- Geothermal Resource Council

- International Hydropower Association

- National Biodiesel Board

- CHP Association

- Evergreen Solar (National Council for Solar Growth)

Others

- Database of State Incentives for Renewable Energy (DSIRE)

- DOE–EERE Bioenergy Basics

- DOE–EERE Alternative Fuels and Advanced Vehicles

- DOE–EERE Geothermal Technologies Office

- DOE–Marine Energy Projects Database

- DOE–EERE Microhydropower Systems

- NREL Biomass Energy Basics

- PVWatts® Calculator

- Wind Resource Data, Tools, and Maps

Americans with Disabilities Act (ADA) Standards

This document contains scoping and technical requirements for accessibility to sites, facilities, buildings, and elements by individuals with disabilities. The requirements are to be applied during the design, construction, additions to, and alteration of sites, facilities, buildings, and elements to the extent required by regulations issued by Federal agencies under the Americans with Disabilities Act of 1990 (ADA).

The Department of Justice (DOJ) updated its ADA Standards in 2010, which are referred to as the 2010 ADA Standards for Accessible Design. These standards, which replace the original ADA Standards DOJ issued in 1991, became mandatory for newly constructed and altered facilities as of March 15, 2012. DOJ’s ADA Standards apply to all facilities covered by the ADA except public transit facilities.

The Department of Transportation (DOT) issued its current edition of the ADA Standards in 2006. These standards apply to facilities used by state and local governments to provide public transportation. They became effective on November 29, 2006 and replace earlier standards issued by DOT in 1991.

Americans with Disabilities Act and Architectural Barriers Act Accessibility Guidelines

This document contains scoping and technical requirements for accessibility to sites, facilities, buildings, and elements by individuals with disabilities. The requirements are to be applied during the design, construction, additions to, and alteration of sites, facilities, buildings, and elements to the extent required by regulations issued by Federal agencies under the Americans with Disabilities Act of 1990 (ADA).

This new design document is the culmination of a comprehensive, decade-long review and update of the Board’s ADA Accessibility Guidelines, which were first published in 1991. Revisions have been made so that the guidelines continue to meet the needs opeople with disabilities and keep pace with technological innovations. For example, new provisions for ATMs specify audible output so that people with vision impairmentare provided equal access, and reach ranges have been lowered to better serve peoplewho use wheelchairs and persons of short stature. The guidelines also feature a new format and organization and have been extensively edited for greater clarity.

As part of this update, the Board has made its guidelines more consistent with model building codes, such as the International Building Code (IBC), and industry standards.It coordinated extensively with model code groups and standard-setting bodies throughout the process so that differences could be reconciled. As a result, a hilevel of harmonization has been achieved which has brought about improvements to thguidelines as well as to counterpart provisions in the IBC and key industry standards, including those for accessible facilities issued through the American National StandardInstitute (ANSI). The Board believes that this achievement will greatly facilitate compliance.

Ammunition & Explosive Magazines

Overview

Within This Page

The purpose of this Building Type page is to assist in the planning and/or design of new Ammunition and Explosive (AE) storage magazines for the Department of Defense (DoD) by providing definitions, descriptions, requirements, and standards of drawings and specifications as available. The information is intended to offer a general introduction into the design and approval of AE storage magazines. For additional information refer to the DoD Component-specific explosives safety documents and the DoD explosives safety manual referenced below.

The Department of Defense Explosives Safety Board (DDESB) has established uniform minimum AE safety standards for personnel and property that have the potential of being exposed to the effects of an accidental explosion. These standards govern the design, construction, and use of all AE storage magazines within the Department of Defense.

Earth Covered Magazine (ECM) structures are built to store AE. They are not designed to resist the damaging effects from an internal explosion, although they can effectively contain the effects from an explosion of very small AE quantities. ECMs are designed to protect their contents and prevent propagation of an explosion that may occur in an adjacent magazine. Proper siting of an ECM, from other Potential Explosion Sites (PES) and Exposed Sites (ES) including operations buildings, piers, aboveground magazines, rail sidings, classification yards, etc, ensures against unacceptable damage and injuries in the event of an accidental explosion.

Facilities are sited from a PES using the appropriate Explosive Safety Quantity- Distance (ESQD) relationship and based upon the Net Explosive Weight (NEW) at the PES.

Explosive safety standards that implement the DoD standards are contained in the following:

- Air Force: AFM 91-201

- Army: AR 385-10 / DA PAM 385-64

- DoD Contractors: DoD 4145.26-M

- Navy: NAVSEA OP 5 Volume 1 (Distribution authorized to U.S. Government agencies and their contractors; administrative/operational use; Other requests for this document must be referred to the Naval Ordnance Safety and Security Activity (NOSSA) (N5))

Description

A. ECM Designs

ECM designs fall within three basic structural hardness classifications; "7-Bar", "3-Bar" and "Undefined" depending upon the relative ability to resist blast loadings. The DDESB has established design criteria for each of the ECM classifications, and approved the classification of previously designed ECMs. DDESB Technical Paper (TP) 15 summarizes the development of AE storage facilities and documents approved protective construction designs.

Approved ECM designs may be site-adapted or tailored to the requirements of a specific site. Site specific tailoring primarily involves adapting the foundation and the drainage system to suit local soil and site characteristics. In addition, certain AE may require additional consideration for utilities, security, electrical, grounding, or humidity and temperature limits.

Any changes to approved designs, other than minimal site adaptation, that in any way may affect the explosive safety of the magazine design will not be used for construction without coordination and approval from the appropriate design agency and from the DDESB.

"7-Bar" (Standard) Designs A 7-Bar ECM provides the highest level of blast resistance and allows the use of the least restrictive siting separation distances. These designs may store up to 500,000 pounds NEW of hazard division 1.1, however some approved designs are based upon a lower storage capacity.

"3-Bar" Designs The headwall and doors of a 3-Bar ECM provides a lower level of blast resistance than a 7-Bar ECM resulting in more restrictive siting separation distances. A 3-Bar ECM may store up to 500,000 pounds NEW of hazard division 1.1, however some approved designs are based upon a lower storage capacity.

"Undefined" (Nonstandard) Designs An Undefined ECM provides the lowest level of blast resistance and requires the greatest siting separation distances. An Undefined ECM may store up to 500,000 pounds NEW of hazard division 1.1, however many of the designs are based upon a lower storage capacity.

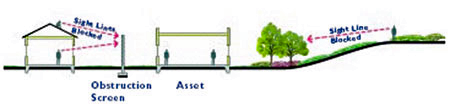

B. Siting Criteria

Siting criteria for ECMs has been developed by the DDESB to define the minimum required separation distances between an ECM as a PES and ES that would be impacted from an accidental explosion. Minimum separation distances have been established between ECM and other magazines, operating buildings, inhabited buildings, and public traffic routes to ensure uniform minimum explosive safety standards for DoD facilities. Minimum separation distances are determined by the level of protection mandated by the applicable explosive safety standard, the ECM classification, the ES type, the quantity and type of AE within a PES, the physical orientation between the PES and the ES and the potential presence of barricading.

For most PES—ES orientations involving an ECM, it can be generally stated that the required siting separation distances are typically greater for a 3-Bar than a 7-Bar ECM and greater still for an Undefined ECM.

C. Approval Requirements

Plans for ECM projects must be reviewed and approved by the DDESB to ensure that minimum DoD explosive safety considerations have been addressed. Situations requiring approval include:

- New construction or major modification

- Changes in utilization of facilities that affect the siting separation distances

If pre-approved ECM designs are used, the project site plan along with the drawing numbers of the ECM design must be submitted for approval.

All new 7- and 3- Bar ECM designs must be approved by the DDESB before they can be used. The approval will require the submission of test results and/or detailed structural calculations.

All new Undefined ECM designs require approval from the DDESB to ensure minimum design and construction criteria are met.

For a description of the minimum requirements to validate explosive safety protective construction see the Department of Defense Explosives Safety Board Memorandum DDESB-PD , dated 21 October 2008.

D. ECM Design Resources

Previous ECM designs have been grouped into four categories described by the following tables. The tables include information related to the design of the magazines including size and maximum stowage capacity. Only the designs within the first category, Table 1, are pre-approved as 7- or 3- Bar ECM Designs for new construction. The source of these tables is DDESB TP 15.

An individual summary page for each of the approved magazine designs is linked from Table 1. Electronic drawing files in PDF format are also provided along with additional information, if available, including guide specifications, AutoCAD or Micro Station drawings that can be downloaded and tailored for site-specific conditions, DDESB approval letters, and other relevant data.

Table 1—7-Bar and 3-Bar ECM Approved for New Construction—The content of this category identifies all 7-Bar and 3-Bar ECM currently approved by the DDESB for new construction. Notes are provided to identify those ECM that have NEW limitations and/or restriction associated with their approval.

Table 2—7-Bar and 3-Bar ECM No Longer Used for New Construction, But Still in Use—The content of this category identifies all ECM designs that previously have been approved for 7- and 3-Bar siting by the DDESB, but are no longer approved for use for new construction. In most cases, these designs have not been updated to satisfy current criteria. The primary intent of this table is to assist activities in siting existing magazines. NEW limitations and/or restrictions associated with their DDESB approval must be observed. These design drawings may be used as the basis for new ECM designs, but they must not be constructed until they are updated to comply with current explosive safety requirements, current construction methods and criteria, and are reviewed and approved by the DDESB. Approved updated design drawings shall clearly identify all changes made to the original design.

If ECM designs from this table are of interest to an activity as new construction, their use must be coordinated with the DDESB to ensure acceptability prior to initiating a project.Table 3—Undefined Earth-Covered Magazines—The content of this category contains ECMs that have not been shown by analysis or testing to be capable of withstanding 7-bar or 3-bar loading. An Undefined ECM is permitted to store up to 500,000 pounds NEW of hazard division 1.1 unless noted otherwise in the table.

An undetermined ECM can be structurally analyzed in accordance with the Joint Service Manual TM5-1300/NAVFAC P-397/AFR 88-22 to determine its structural capabilities. Upon approval of the structural analysis supporting the magazine classification by the DDESB, the ECM design classification may be upgraded. For a listing of Undefined ECM designs see Table AP1-3 of DDESB Technical Paper (TP) 15Table 4—Magazines (Earth-covered and Aboveground) and Containers that have reduced net explosives weight (NEW) and/or reduced quantity-distance (QD)—The contents of this category lists a number of AE storage structures and containers that have been approved by the DDESB for specific NEW and/or reduced QD. These items were generally designed for a particular application; however, as approved items, they can be used for other applications, providing all conditions, restrictions, design elements, etc., are observed. All documentation pertaining to the use of the storage structure or container must be obtained prior to their use. Table AP1-4 of TP-15 identifies restrictions or conditions for the use of these magazines or containers.

E. Typical ECM Features

A semicircular arch or oval arch constructed of reinforced concrete or steel, or a combination of the two. It could also be a reinforced concrete box-type design.

A reinforced concrete floor slab that is typically sloped for drainage.

A reinforced concrete rear wall.

Design blast loads apply to headwalls of 7- and 3-bar ECM and to the roof of box-type magazines.

A reinforced concrete headwall that extends at least 2-1/2 feet above the top of the roof. The headwall is designed to withstand the blast pressures and impulses that will be experienced as a result of an explosion in an adjacent AE storage facility. This is a critical feature that is directly associated with the strength designation assigned to an ECM.

Heavy steel doors in the headwalls (either manually operated or motorized). Approved box-type ECM may have as many as five of these doors in their headwall. Doors are either of the swinging doors or sliding type. Sliding doors are generally used on the larger ECM, while swinging doors are primarily used on smaller ECM. Doors are designed to withstand the dynamic forces from an explosion in an adjacent AE storage facility, and are therefore, a critical element of an ECM design.

Earth cover over the top, sides, and rear of the ECM. A minimum of 2 feet (24 inches) of earth cover is required over the ECM.

Reinforced concrete wingwalls on either side of the headwall. The wingwalls may slope to the ground or may join wingwalls from adjacent ECM. The purpose of wingwalls is to retain the earth fill along the side slopes of the ECM.

Lightning protection and grounding systems. Reinforcing steel in the walls, floor, and roof must be electrically continuous to provide electrical bonding between the elements and produce a faraday-like shield. Techniques commonly used and approved in the construction industry to join reinforcing steel are acceptable. The steel arch of an ECM must be similarly joined to the reinforcing steel in the floor. Minimum resistance valves apply. Other metal masses, such as ventilators, shall also be grounded and connected to a common earth electrode system such as a buried ground girdle.

Incoming utilities are installed to meet the material, installation, grounding, and lightning surge protection criteria.

When required, internal electrical work and equipment must be rated for the hazardous environments expected within the ECM.

In the case of a box-type ECM, the walls and roof may be constructed of reinforced concrete or of prefabricated concrete panels that are assembled in the field. Earth cover, lightening, and grounding criteria described above also applies to box-typed ECM.

F. ECM Types

Listed below are the descriptions of the cross-section of magazines.

Arch—Also known as a circular arch. A single radius is used to define the interior face of the arch, which may be constructed of reinforced concrete, steel (corrugated, laminated, or single gage), or a combination of reinforced concrete and steel to form a composite arch (steel interior arch with overlying concrete).

Arch, Oval—This arch is in the shape of an oval, with the lower portion of each sidewall bowing in towards the direction of the centerline. The arch can be constructed of steel, reinforced concrete, or a composite of both. The shape is defined by the use of a single radius for the majority of the arch, with a separate radius called out for the lower portions of the arch. The modified FRELOC-Stradley ECM design is an example of an oval-arch ECM.

Arch, Semi-Circular—The sidewalls are elongated with the arch defined by a radius that originates approximately 3 to 5 feet above floor level. A radius originating at the opposite sidewall defines the lower portion of the arch. The arch can be constructed of either reinforced concrete or steel.

Stradley—This reinforced concreted ECM is characterized by vertical sidewalls that blend into the arched roof. Three radii are used to define the arch and the transition from the vertical sidewalls to the roof arch. Another feature of the Stradley ECM is that its walls are significantly thicker at the base of the sidewalls and thinner at the crown of the arch. There are currently no Stradley designs approved for new construction.

FRELOC-Stradley—The FRELOC-Stradley ECM is constructed of reinforced concrete. Its interior shape is similar to a Stradley ECM, except that the sidewalls and arch have the same thickness.

Modified FRELOC-Stradley—This ECM design was the first ECM constructed with an oval arch. See the information above for the oval arch. There are currently no Modified FRELOC Stradley designs approved for new construction.

Box—This term describes any ECM that has an internal box shape. Explosives limits can range from less than a pound NEW of hazard division 1.1 to 500,000 pounds NEW hazard division 1.1.

Dome—The domed shape is used for only the Corbetta ECM design. The interior wall is approximately three times the height of the magazine. There are currently no Dome designs approved for new construction.

G. ECM Selection

The selection of an ECM is based primarily on the type and quantity of AE that will be stored in the magazine and the cost of construction. Siting restrictions, potential operational considerations, AE compatibility, and other considerations may also factor in the selection of the magazine.

Individual summary sheets for each of the approved 7- and 3- Bar ECM designs within Table 1 are provided to help in the selection process. The information provided in the summary sheets include the physical dimensions of the magazine, approved drawing number, number and size of doors, maximum NEW storage capacity, and comments related to the use of the design.

Individual services may also provide additional guidance on the selection of magazine designs.

Suggested storage layout plans for various AE within many of the approved magazine designs are available to assist in the effective use of the magazine and as a tool to estimate the potential stowage capacity. The U.S. Army Technical Center of Explosives Safety (USATCES) develops and maintains several tools and documents related to the storage of AE.

- NAVSEAINST 8024.2

- U.S. Army Command drawings 19-48-75-5

H. Barricades

Barricades are protective structures that can act as a barrier between a PES and an ES. When properly sited and constructed they are an effective protection against low angle fragments and for reducing shock overpressures near the barricade. To protect against low angle fragments barricades must be high enough to intercept the ballistic trajectories of fragments and thick enough to reduce the fragment velocity to acceptable levels.

Army Definitive Drawings for Barricades Standard Design (Drawing Code DEF 149-30-01) illustrates several conceptual barricade designs utilizing various construction materials. For additional information see DoD Explosives Safety or the applicable service explosive safety standards.

Relevant Codes and Standards

- AR 385-10 The Army Safety Program by Department of the Army.

- AFM 91-201 Explosives Safety Standards by HQ USAF/SE.

- DA PAM 385-64 Explosives Safety Standards by Department of the Army.

- DoD 4145.26-M DoD Contractors' Safety Manual for Ammunition and Explosives by Under-Secretary of Defense for Acquisition and Technology.

- DESR 6055.09 Defense Explosives Safety Regulation by Under-Secretary of Defense for Acquisition and Sustainment

- NAVSEA OP 5 Volume 1 Ammunition and Explosives Safety Ashore, Department of the Navy, Naval Sea Systems Command (Distribution authorized to U.S. Government agencies and their contractors; administrative/operational use; Other requests for this document must be referred to the Naval Ordnance Safety and Security Activity (NOSSA) (N5)).

Additional Resources

Websites

- The Air Force Sustainment Center

- The Defense Ammunition Center

- The Naval PHST Center

- The Naval Safety Center

- The U.S. Army Engineering and Support Center, Huntsville, AL

- The U.S. Army Technical Center for Explosives Safety

Publications

- DDESB TP 15 Approved Protective Construction by Department of Defense Explosive Safety Board.

- DDESB-PD Memorandum, 21 Oct 2008, Minimum Requirements to Validate Explosives Safety Protective Construction by Department of Defense Explosives Safety Board.

- EP 1110-345-102 Engineering and Design Explosives Storage Magazines by Department of the Army, Army Corps of Engineers.

- NAVSEAINST 8024.2 Magazine Stowage Layout Standards by Department of the Navy, Naval Sea Systems Command.

- TM 5-1300/NAVFAC P-397/AFR 88-22 Structures to Resist the Effects of Accidental Explosions by Departments of the Army, the Navy, and the Air Force.

- U.S. Air Force Munitions Facilities Standards Guide, Vol. 1

- U.S. Air Force Munitions Facilities Standards Guide, Vol. 2

- U.S. Army Material Command Drawings 19-48-75-5 by U.S. Army Ammunition Center and School (USADACS).

Drawings

Ammunition and Explosive Storage Magazines: ECM Approved for New Construction

The content of this category identifies all 7-Bar and 3-Bar ECM currently approved by the DDESB for new construction. Notes are provided to identify those ECM that have NEW limitations and/or restrictions associated with their approval.

Select a drawing number to view and download files associated with that ECM.

These documents are available in the following formats: Adobe Acrobat (PDF) | CAD in compressed ZIP | DWG

Description | Drawing Number | Dimensions | Door Opening | Weight |

|---|---|---|---|---|

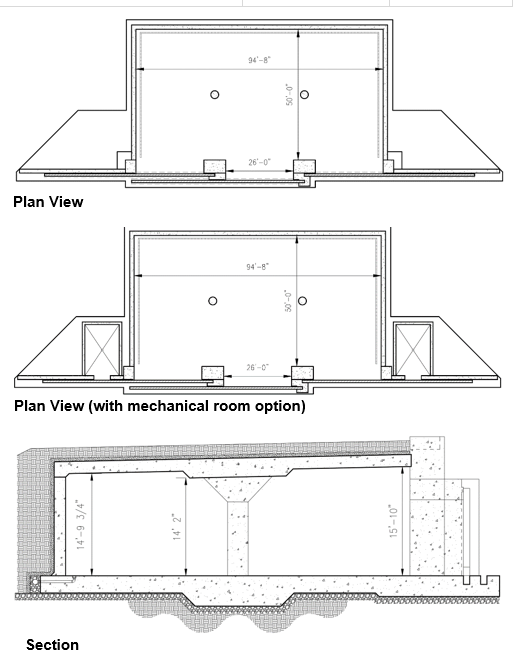

Type G Box ECM Standard Drawings | 14145654 through 14145739 | 94'-8" Wide x 50'-0" Long x 14'-9.75" (Rear) To 15'-10" (Front) High | (3) Sliding 26'-0" Wide x 11'-0" High | 500,000lb |

Approved Files for UseDocumentationComments/Design ConsiderationThe Type G Box ECM has been designed for the storage of munitions. The design of this structure was based on the design of the existing Navy Type C Box ECM, updated to comply with current design criteria, address operational issues noted in previous designs, and improve overall ability to support the Navy explosive storage needs moving forward. Due to the comprehensive nature of the updates to the Type C Box magazine, it has been completely redesigned and renamed the Type G Box magazine. The interior horizontal dimensions of the Type G are the same as the Type C. The clear height, from floor to ceiling, at the front interior space is the same as the Type C, however the roof slope was decreased which increases the clear height, from floor to ceiling, at the rear of the interior space. The columns and door openings have been shifted slightly to promote symmetry, ease of construction, and better efficiency. The exterior walls are thicker, and a mat slab design was used for the foundation. Mechanical rooms were included as site adapt options. The pilasters and header beams have been reconfigured to better absorb and dissipate blast hazards in a detonation scenario, and the blast door includes enhanced physical security features, an automated trench plate lifting system, and a bottom-supported wheel and rail system.  | ||||

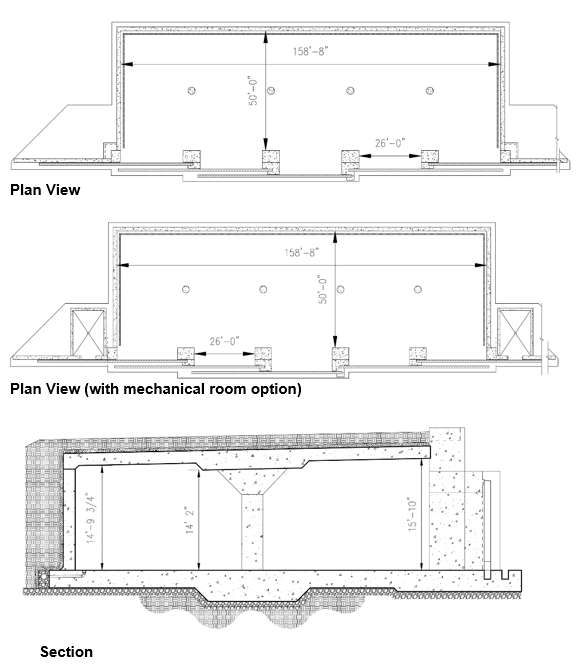

Type H Box ECM Standard Drawings | 14138777 through 14138861 | 158'-8" Wide x 50'-0" Long x 14'-9.75" (Rear) To 15'-10" (Front) High | (5) Sliding 26'-0" Wide x 11'-0" High | 500,000lb |

Approved Files for UseDigital DrawingsDocumentationComments/Design ConsiderationThe Type H Box ECM has been designed for the storage of munitions. The design of this structure was based on the design of the existing Navy Type D Box ECM, updated to comply with current design criteria, address operational issues noted in previous designs, and improve overall ability to support the Navy explosive storage needs moving forward. Due to the comprehensive nature of the updates to the Type D Box magazine, it has been completely redesigned and renamed the Type H Box magazine. The interior horizontal dimensions of the Type H are the same as the Type D. The clear height, from floor to ceiling, at the front interior space is the same as the Type D, however the roof slope was decreased which increases the clear height, from floor to ceiling, at the rear of the interior space. The columns and door openings have been shifted slightly to promote symmetry, ease of construction, and better efficiency. The exterior walls are thicker, and a mat slab design was used for the foundation. Mechanical rooms were included as site adapt options. The pilasters and header beams have been reconfigured to better absorb and dissipate blast hazards in a detonation scenario, and the blast door includes enhanced physical security features, an automated trench plate lifting system, and a bottom-supported wheel and rail system.  | ||||

Single Bay CLWS Navy ECM Standard Drawings | 12905820 through 12905870 | 119'-0" Long x 32'-0" Wide | 32'-0" Wide x 14'-0" High | 500,000lb |

Approved Files for UseComments/Design ConsiderationThese drawings represent the single bay configuration of the Containerized Long Weapons Storage (CLWS) Navy Earth Covered Magazines, approved by DDESB on 25 July 2024. All new construction of single bay CLWS Magazines will be in accordance with drawings 12905820 through 12905870. The Single Bay CLWS ECM is a cast-in-place reinforced concrete box magazine 32 ft-wide. The magazine can be built 95'-6" or 119' long and has a minimum interior height of 24'-8", with a transverse roof slope of 1/4" per foot. The roof, side and rear walls, and headwall of the magazine consist of 24" thick concrete walls. The blast door of the magazine consists of a single sliding steel door, spanning vertically between a bottom trench and a header beam, covering a 14-ft tall, 32-ft wide opening. This header beam frames into pilasters located at the intersection of the headwall and sidewalls. The blast door includes enhanced physical security features, an automated trench plate lifting system, and a bottom-supported wheel and rail system. | ||||

Double Bay CLWS Navy ECM Standard Drawings | 12914696 through 12914757 | 114'-0" Long x 50'-0" Wide x (minimum) 24'-7 1/2" high | 32'-0" Wide x 14'-0" High | 500,000lb |

Approved Files for UseComments/Design ConsiderationThese drawings represent the double bay configuration of the Containerized Long Weapons Storage (CLWS) Navy Earth Covered Magazines, approved by DDESB on 26 January 2025. All new construction of double bay CLWS Magazines will be in accordance with drawings 12914696 through 12914757. The Double Bay CLWS ECM is a novel reinforced concrete box-type design with two bays separated by an interior reinforced concrete wall. Each bay has clear interior dimensions of 114'-0" length by 50-'0" width by minimum 24'-7 1/2" height. The front wall of each bay has a door opening with clear dimensions of 32'-0" width by 14'-0" height. The design also includes optional interior bridge crane and two mechanical rooms for environmental controls. | ||||

Navy Modular Storage Magazine Version 2 | 14148449 through 14148533 | 25'-0" Wide x 81'-6" Long x 14'-8" High | (1) Sliding | 500,000lb |

Approved Files for UseComments/Design ConsiderationThese drawings represent the new design of Navy Modular Storage Magazine (MSM) Version 2, approved by DDESB on 28 April 2025. All new construction of MSMs will be in accordance with drawings 14148449 through 14148533. | ||||

Navy Modular Storage Magazine | ||||

RC Box Type 'M' | ||||

RC Box Type 'C' | ||||

RC Box Type 'D' | ||||

RC Circular Arch | ||||

Composite Circular Arch | ||||

Composite Oval Arch | ||||

RC Box Type 'E' | ||||

RC FRELOC Stradley | (Korean Version) | 25'-0" Wide x 87'-0" Max. Length (normally length is 60' or 80') x 13'-0" (Rear) High | (1) Sliding | 500,000lb |

Approved Files for UseComments/Design ConsiderationThis design is the latest approved version of the Republic of Korea Army (ROKA) drawing for 33-15-74. The original basis for the Korean version was U.S. Army COE 33-1-74. The Korean drawings assure that all reinforcing steel is electrically continuous. The previous version of this drawing was approved by the DDESB as a 7-bar magazine on 25 May 2002.  | ||||

RC FRELOC Stradley | (Modified Korean Version) | 25'-0" Wide x 87'-6" Max. Length (normally length is 60' or 80') x 13'-0" (Rear) High | (1) Sliding | 500,000lb |

Approved Files for UseComments/Design ConsiderationThis design is a modified version of the Republic of Korea Army (ROKA) drawing for 33-15-74. The original basis was U.S. Army COE 33-1-74. The Korean drawings assure that all reinforcing steel is electrically continuous. The Modified version includes provisions for air conditioning the magazine. The original version of this drawing was approved by the DDESB as a 7-bar magazine on 25 May 2002.  | ||||

Steel, Semi-Circular Arch | 421-80-01 | Approx. 26'-0" Wide x 19'-0" Min. expandable up to most commonly used 89'-0" Length x 14'-0" (Max.) High | (1) Sliding | 500,000lb |

Approved Files for UseNone at this time. Comments/Design ConsiderationUnder Army Review, Not Approved for New Construction If a steel arch ECM is required, use standard drawings 421-80-03, Steel Oval Arch. Contact HNC and USATCES for additional guidance on appropriate site adapt of the 421-80-03 standard.  | ||||

Steel Oval Arch | 421-80-03 | 28'-2" (Max.) Wide x 21'-0" Min. to 89'-0" Max. Length x 14'-11" (Max.) High | (1) Sliding | 500,000lb |

Approved Files for UseComments/Design ConsiderationReplaced 33-15-73. Arch design composed of a 1-gauge (0.280 inch) corrugated steel arch. The site-adapt Designer of Record shall ensure DoD and Army explosives safety requirements for Lightning Protection and Grounding are met. The Designer of Record shall obtain review support and technical concurrence of the site-adapt design from the U.S. Army Corps of Engineers Engineering and Support Center, Huntsville.  | ||||

RC Arch | 421-80-05 | 26'-7 1/4" Wide x 90'-0" Max. Length (normally length is 60' or 80') x 14'-0" (Rear) High | (1) Sliding | 500,000lb |

Approved Files for UseDigital Drawings

DocumentationComments/Design ConsiderationConstructed using the Techspan Precast Concrete System, developed by the Reinforced Earth Company, for each construction. The headwall and door are derived for 33-15-74.  | ||||

RC Box | 421-80-07 | 25'-0" Wide x 20'-0" Min. to 80'-0" Max. Length x 11'-0" High | Hinged | 500,000lb |

Approved Files for UseDigital Drawings

DocumentationComments/Design ConsiderationMSM Standard 421-80-07 replaces the previous MSM Standard 421-80-06 (modified). The new series updates the drawings to meet current AEC CAD standards, improved plan readability, constructability, and correct omissions within the construction drawings. Another key element performed during the revision was the incorporation of lessons learned from previous MSM projects at various user organizations. In addition to the drawings, a conventional structural load analysis was performed to identify some key loading limits, which will assist the designer during the site-adaption process.  | ||||

Modular Storage Magazine, Box-Type | 421-80-08 | 25'-0" Wide x 20'-0" Min. to 80'-0" Max. Length x 14'-8" High | Hinged | 500,000lb |

Approved Files for UseDigital Drawings

DocumentationComments/Design ConsiderationThe MSM Box-Type Standard 421-80-08 replaces the previous Munitions Storage Magazine (14 feet ceiling height) as designed for Hill AFB. The new series updates the drawings to meet current AEC CAD standards, and features improved plan readability, constructability, and corrects omissions within the construction drawings. Another key element performed during the revision was the incorporation of lessons learned (see Appendix of Design Narrative) from previous MSM projects at various user organizations. In addition to the drawings, a conventional structural load analysis was performed to identify some key loading limits, which will assist the designer during the site-adaption process.  | ||||

ECM, Concrete Oval-Arch | 421-80-09 | 25'-0" Wide x 90'-0" Max. Length (normally length is 60' or 80') x 14'-0" (Rear) High | (1) Sliding | 500,000lb |

4Approved Files for UseDigital Drawings

DocumentationComments/Design ConsiderationCOE Standard 421-80-09 replaces the previous COE Standard 33-15-74. The new series updates the drawings to meet current AEC CAD standards, improves plan readability, constructability, and corrects omissions within the construction drawings. Headwall components have been re-analyzed under the 7-bar blast loading from DoD 6055.09-M using the methodology of UFC 3-340-02. The remaining components are as originally designed. In addition to the drawings, a conventional structural load analysis was performed to identify some key loading limits, which will assist the designer during the site-adaption process and a new retaining wall design was completed to simplify construction of the wing walls. The documentation will not include specifications.  | ||||

USACE Modular Storage Magazine Box–Type Flow–Thru | 421-80-10 | (internal): x 4470mm High | (2) Hinged | 500,000lb |

Approved Files for Use | ||||

USACE Modular Storage Magazine Box–Type European Version | 421-80-13 | (internal): x 4470mm High | (1) Sliding | 500,000lb |

Approved Files for Use | ||||

RC Box Type 'D' | 6448555 through 6448588 | 158'-8" Wide x 50'-0" Long x 13'-8" (Rear) To 15'-10" (Front) High | (3) Sliding | 500,000lb |

Approved Files for UseComments/Design ConsiderationUnder Navy Review. Contact NAVFAC LANT, Code CI42 This design is identical to NAVFAC 6448522 through 6448554, Box Type D, except that it incorporates a High Security Integrated Locking System (HSILS).  | ||||

RC Box Type 'F' | ||||

RC Box | Munitionslagerhause | |||

Steel Oval Arch | Munitionslagerhause | |||

RC Box | Munitionslagerhause | |||

Steel Oval Arch | Munitionslagerhause | |||

Ammunition and Explosive Storage Magazines: ECM No Longer Used for New Construction, but Still in Use

The content of this category identifies all ECM designs that previously have been approved for 7- and 3-Bar siting by the DDESB, but are no longer approved for use for new construction. In most cases, these designs have not been updated to satisfy current criteria. The primary intent of this table is to assist activities in siting existing magazines. NEW limitations and/or restrictions associated with their DDESB approval must be observed. These design drawings may be used as the basis for new ECM designs, but they must not be constructed until they are updated to comply with current explosive safety requirements, current construction methods and criteria, and are reviewed and approved by the DDESB. Approved updated design drawings shall clearly identify all changes made to the original design.

If ECM designs from this table are of interest to an activity as new construction, their use must be coordinated with the DDESB to ensure acceptability prior to initiating a project.

Select a drawing number to view and download files associated with that ECM.

These documents are available in the following formats:

Adobe Acrobat (PDF) | CAD in compressed ZIP

| Description | Drawing Number | Relationship to Other Drawings | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Steel Arch | 1059128-1059130 Modifications 1059132, 1069906, 1355460 and 1355461 | Reference 1351905 | ||||||||||||||||

Reference Information - Steel Arch

Digital Drawings

Comments/Design ConsiderationThere is no reduced ESQD associated with this ECM design. |

||||||||||||||||||

| RC Box, Type 'A' | 1404000-1404007 | Supersedes 749771-749774 and 793751 | ||||||||||||||||

Reference Information - RC Box, Type 'A'

Comments/Design ConsiderationSupersedes Drawings 749771-749774 and 793751. NAVFAC MIL-BUL-340 (YD), Jul 93, lists these ECM drawings as canceled. |

||||||||||||||||||

| RC Box Type 'B' | 1404018-1404025 and 952132-952134 | Supersedes 952127-952131 and 952135 | ||||||||||||||||

Reference Information - RC Box Type 'B'

Comments/Design ConsiderationSupersedes Y & D Drawings 952127-952131 and 952135. NAVFAC MIL-BUL-340 (YD), Jul 93, lists these ECM drawings as canceled. |

||||||||||||||||||

| RC Box Type 'C' | 1404430-1404444 | Superseded by 14004689-14004720 and 14005091-14005122 | ||||||||||||||||

Reference Information - RC Box Type 'C'

Comments/Design ConsiderationDDESB approval signature of 11 May 85 on drawings. Replaced by RC Box, Type 'C' - NAVFAC 14004689-14004720 (Without Platform) and NAVFAC 14005091-14005122 (With Platform) |

||||||||||||||||||

| RC Box Type 'C' | 14004689-14004720 and 14005091-14005122 | Superseded by 14004689-14004720, Rev. 1 and 14005091-14005122, Rev. 1 | ||||||||||||||||

Reference Information - RC Box Type 'C'

Digital Drawings

DocumentationComments/Design ConsiderationDDESB approval signature of 04-Jan-2011 on drawings. Replaced by RC Box, Type 'C' - NAVFAC 14004689-14004720, Rev. 1 (Without Platform) and NAVFAC 14005091-14005122, Rev. 1 (With Platform) |

||||||||||||||||||

| Steel Oval Arch | 1404026-1404034 | |||||||||||||||||

Reference Information - Steel Oval Arch

Comments/Design ConsiderationListed in DDESB minutes as STD magazine. NAVFAC MIL-BUL-340 (YD), Jul 93, lists these ECM drawings as canceled. |

||||||||||||||||||

| Steel Arch | 1404328-1404342 | Supersedes 1059128-1059130, 1059132, 1069906 and 1355460-1355461 | ||||||||||||||||

Reference Information - Steel Arch

Digital Drawings

|

||||||||||||||||||

| RC Box, Type 'D' | 1404465-1404478 | Superseded by 6448522-6448554 and 6448555-6448588 | ||||||||||||||||

Reference Information - RC Box, Type 'D'

DocumentationComments/Design ConsiderationDDESB (P. Price) approval signature of 05 Nov. 85 on drawings. Sited for 350,000 pounds NEW. Superseded by NAVFAC Drawings 6448522-6448554 (Standard Box Magazine Type D) and NAVFAC Drawings 6448555-6448588 (HSLIS Box Magazine Type D), both dated 27 May 97. |

||||||||||||||||||

| RC Box, Type 'D' | 6448522-6448554 | Superseded by 14021368-14021404 and 14021406-14021444 | ||||||||||||||||

Reference Information - RC Box, Type 'D'

Digital DrawingsDocumentationComments/Design ConsiderationSuperseded NAVFAC 1404465 through 1404478. DDESB approval signature of 30 June 87 on original drawings. Replaced by RC Box, Type 'D' - NAVFAC 14021368-14021404 (Without Platform) and NAVFAC 14021406-14021444 (With Platform) |

||||||||||||||||||

| RC Box, Type 'D' | 14021368-14021404 and 14021406-14021444 | Superseded by 18232899-18232936 and 18232939-18232978 | ||||||||||||||||

Reference Information - RC Box, Type 'D'

Digital Drawings

DocumentationComments/Design ConsiderationSuperseded NAVFAC 6448522 through 6448554. DDESB approval signature of 13 March 13 on original drawings. Replaced by RC Box, Type 'D' - NAVFAC 18232899-18232936 (Without Platform) and NAVFAC 18232939-18232978 (With Platform) |

||||||||||||||||||

| RC Box, Type 'F' | 1404541-1404555 | Superseded by 6448589-6448621 | ||||||||||||||||

Reference Information - RC Box, Type 'F'

Comments/Design ConsiderationSuperseded by NAVFAC Drawings 6448589-6448621. This magazine design was sited for 350,000 pounds NEW. A site specific approval was granted to Naval Weapons Station, Seal Beach, for the construction of four Box Type F Magazines with the dehumidification system located on top of the Magazine, vice behind the magazines as was shown on the approved design drawings. This modification was not approved by the DDESB as a standard design, since the Navy never came in with a modified standard magazine drawing set to incorporate the addition of the dehumidification system onto the magazine roof. |

||||||||||||||||||

| RC FRELOC Stradley | 219-25-321 | Based on 33-15-74 | ||||||||||||||||

Reference Information - RC FRELOC Stradley

Digital DrawingsComments/Design ConsiderationThis design was constructed at Luke AFB. It was evaluated by the COE, Huntsville, to determine its structural rating. Their analysis, documented on memo CEHNC-ED-CS-S(210.2b) of 23 January 2002, found that the design shown on the drawings came from existing 7-Bar ECM design 33-15-74. |

||||||||||||||||||

| RC Stradley | 33-03-0028 | Based on 33-15-61 | ||||||||||||||||

Reference Information - RC Stradley

Comments/Design ConsiderationThis design was constructed at Osan Air Base, Korea and is based on OCE Drawing 33–15-61, 30 Dec, 1959, which is considered a 7-Bar ECM. The drawings provides for two different ECM designs. One design is a typical ECM with a single headwall and the ventilator out the rear of the ECM, while the second design includes two headwalls and a ventilator that is centered on the roof of the ECM. Based on a review by the Huntsville COE, the headwall and doors used on 33-03-0028 match the headwall and doors of 33-15-61. The doors of the three designs are all 6-foot wide sliding doors. Two of these doors are required per entrance. |

||||||||||||||||||

| RC FRELOC Stradley | 33-03-31 | Similar to 33-15-61 | ||||||||||||||||

Reference Information - RC FRELOC Stradley

Comments/Design ConsiderationThis design is similar to 33-15-61, the DDESB approved Standard Freloc-Stradley Magazine. 3-03-31 was designed for construction at VILSECK ASP-I (Germany) for USAFE. It measured 26' W X 80' L and had a ceiling height of 14' at the centerline. The entrance measured approximately 10' by 10'. It had a reinforced concrete arch of uniform thickness. a heavily reinforced headwall, and bi-parting, double-leaf steel doors. A Sep 1977 dynamic analysis of this Freloc design, performed by Agbabian Associates for the COE, European Division, determined that the headwall was sufficiently strong to meet NATO face-on loading criterion, but the door was not. Recommendations were prodded in Agbabian Associates Report R-7745-4503 to strengthen the doors by adding additonal horizontal and vertical stiffeners on the exterior side of the doors. DDESB-KT Memos of 27 Jan and 4 May 1978 states that the door of the ECM analyzed by Agbabian Associates (33-03-31) met U.S. standard magazine criteria. |

||||||||||||||||||

| RC Arch | 33-03-43 | Compared to 33-15-61 and 33-15-64 | ||||||||||||||||

Reference Information - RC Arch

Comments/Design ConsiderationKnown as a Quick Reaction Site (QRS) magazine, which were only constructed in Germany. Permitted to store a maximum of 4,000 kg NEQ. DDESB-KT Memo of 19 March 1976 evaluated this design and compared its structural components to counterpart features of standard ECM, particularly those in 33-15-61 and 33-15-64, which had undergone extensive testing. Based on this review, the design was approved for she storage of 4,000 kg NEQ in each arch unit. In addition, the design of the door was considered to qualify the ECM design for the minimum separation distances permitted. |

||||||||||||||||||

| RC Stradley | 33-13-02 | Revision of 33-15-06 | ||||||||||||||||

Reference Information - RC Stradley

DocumentationComments/Design ConsiderationA COE, Huntsville District, letter of 13 Apr 98 determined this ECM was a revision of 33-15-06 (a 7-Bar ECM) and recommended it be considered a 7-Bar ECM as well. A 26 Jan 99 DDESB letter approved use of ECM constructed in accordance with Drawing 33-13-02, as a 7-Bar magazine. A provision of the approval was that the separation distances between the rear or side of these ECMs, as the PES, to the front of one of these ECMs, as an ES, was at least 360 feet. Side to side exposures between the PES and the ES are required to be separated in accordance with the appropriate entries for either 3-bar or 7-bar ECMs in accordance with Table 9-5 of DoD 6055.9-ST:). |

||||||||||||||||||

| RC Stradley | 33-15-01 | Consistent with AW33-15-01 | ||||||||||||||||

Reference Information - RC Stradley

Digital Drawings

Comments/Design ConsiderationA double-headwall (flow-through) design with a single sliding door on each headwall. The headwall and door design are consistent with the COE, Omaha District. ALCM magazine design (AW 33-15-01), a 7-Bar design. |

||||||||||||||||||

| RC Stradley | AW33-15-01 | |||||||||||||||||

Reference Information - RC Stradley

Digital DrawingsDocumentationComments/Design ConsiderationThis design was known as the Air Launched Cruise Missile (ALCM) Igloo and is a double-headwall (flow-through) design with two large sliding doors on each headwall. The design provides 7-Bar protection. A 26 Feb 1980 DDESB letter approved AW 33-15-01 as a typical layout for ALCM storage and considered this design equal to a standard ECM. There are two designs in existence, with the only differences being the footings and floor slab. The initial design constructed at Griffis AFB, NY, had wall footings and a floating slab-on-grade. The subsequent design revised the foundation and flooring to a mat foundation slab. The subsequent design is believed to have been constructed at the following Air Force Bases: Grand Forks, ND. Minot. ND: Fairchild, WA. Ellsworth.. SD: Wurtsmith, WI; K.I. Sawyer, MI; Barksdale. LA; Blythville. AR: McConnel.. KS: Carswell, TX; and Andersen, Guam. Internal dimensions are 40' wide by 112' long by 18'6" high along the longitudinal centerline. Each of the sliding doors measures 18' 10" long by 13'7 5/8" high. |

||||||||||||||||||

| RC Arch | AW33-15-02 | |||||||||||||||||

Reference Information - RC Arch

Comments/Design ConsiderationConstructed at Luke AFB, analyzed by COE- Huntsville, to determine its Structural rating. Their analysis, documented on memo CEHNC-ED-CS-S (210-2b) of 23 January 2002, found that the design of the headwall and door meets 7-Bar criteria. |

||||||||||||||||||

| Steel, Oval Arch | 33-15-02 | |||||||||||||||||

Reference Information - Steel, Oval Arch

Digital DrawingsComments/Design ConsiderationA double-headwall (flow-through) design with a single sliding door on each headwall. The headwall and door design are consistent with the COE, Omaha District, ALCM magazine design (AW 33-15-01), a 7-Bar design. |

||||||||||||||||||

| RC Arch | 33-15-02 | |||||||||||||||||

Reference Information - RC Arch

Comments/Design ConsiderationConstructed at Barkesdale AFB, LA. Analyzed by COE, Huntsville AL, to determine structural rating. Their analysis, documented on memo CEHNC-ED-CS-S of 15 July 2003 found that the design of the headwall and doors met 7-Bar criteria. |

||||||||||||||||||

| RC Stradley | 33-15-03 | Similar to 33-15-01 | ||||||||||||||||

Reference Information - RC Stradley

Digital DrawingsComments/Design ConsiderationA double-headwall (flow-through) design with a single sliding door on each headwall. The headwall and door design are consistent with the COE. Omaha District ALCM magazine design. Similar design to Omaha District 33-15-01, but with a larger door opening. |

||||||||||||||||||

| Steel Oval Arch | 33-15-04 | Similar to 33-15-02 | ||||||||||||||||

Reference Information - Steel Oval Arch

Comments/Design ConsiderationA double-headwall (flow-through) design with a single sliding door on each headwall. The headwall and door design are consistent with the COE, Omaha District ALCM magazine design. Similar design to Omaha District 33-15-02, but with a larger door opening. |

||||||||||||||||||

| RC Arch | 33-15-06 | Previously called the "YURT" Magazine, this design Superseded drawings 652-686 through 652-693 and 33-15-01 | ||||||||||||||||

Reference Information - RC Arch

Digital DrawingsComments/Design ConsiderationPreviously called the "YURT" Magazine. This magazine design superseded Drawings 652-686 - 33-15-01. A 1 Apr 87 Huntsville Division, COE, letter stated that ECM design 33-15-06 was no longer being used for new construction. ECM separation distances based in the following criteria: Side to side - use 1.5W" 1/3; back to back - 1.5W 1/3; front to back - 4.5W 1/3 |

||||||||||||||||||

| RC FRELOC Stradley | 33-15-13 | |||||||||||||||||

Reference Information - RC FRELOC Stradley

Digital DrawingsComments/Design ConsiderationA 4 May 78 DDESB letter restated that 33-15-13 was a standard ECM and that variations of this design were acceptable, provided new designs were at least equal to it structurally. This design is known as the "thin-wall" magazine and is known to have been built at Camp Darby, Italy. Similar designs, based on the 33- 15-13 design are known to have been constructed in Germany and elsewhere. |

||||||||||||||||||

| Modified FRELOC Stradley (Steel Oval Arch) | 33-15-15 | |||||||||||||||||

Reference Information - Modified FRELOC Stradley (Steel Oval Arch)

Digital Drawings

Comments/Design ConsiderationThis design includes a double leaf door system, similar to the 33-15-61 two-leaf sliding door tested as part of ESKIMO 11. |

||||||||||||||||||

| RC FRELOC Stradley | 33-15-16 | Also known as Type 16 Magazine Corrected deficiencies with 33-15-14 | ||||||||||||||||

Reference Information - RC FRELOC Stradley

DocumentationComments/Design ConsiderationAlso known as the "Type16" Magazine. This design corrected strength deficiencies found in ECM design 33-15-14, which was determined to be non-standard ECM. |

||||||||||||||||||

| Steel Arch | 33-15-208 | |||||||||||||||||

Reference Information - Steel Arch

Comments/Design ConsiderationReplaced design 33-15-28 that was previously approved by DDESB for construction at Larson Barracks, Kitzingen, GE. This design has only one entrance vice the 2 shown on 33-15-28. |

||||||||||||||||||

| Steel Arch | 33-15-28 | |||||||||||||||||

Reference Information - Steel Arch

Comments/Design ConsiderationConstructed at Larson Barracks, Kitzingen, GE. Based on QRS magazine. which were only constructed in Germany (see 33-03-43 design). This design had 2 front headwalls and doors and no rear wall. |

||||||||||||||||||

| RC Stradley | 33-15-58 | Replaced YT-1-1 through YT-111 Constructed in accordance with 33-15-58 and 33-15-61 | ||||||||||||||||

Reference Information - RC Stradley

Comments/Design ConsiderationApproved during 259th ASESB meeting of 14 Oct 70 and was considered to be atomic blast resistant. This drawing replaced former drawings YT -1 -1 though YT-111. At that meeting, the Chairman, ASESB, also read into the record that Stradley (Yurt) magazines which are constructed in accordance with Standard OCE Drawings 13-15-58 and/or 33--15-61 are considered to be equivalent in strength to the OCE's standard earth covered igloo magazines. |

||||||||||||||||||

| RC Stradley | 33-15-61 | Replaced YT-1-1 through YT-111 Constructed in accordance with 33-15-58 and 33-15-61 | ||||||||||||||||

Reference Information - RC Stradley

Digital DrawingsComments/Design ConsiderationApproved during 259th ASESB meeting of 14 Oct 70. This drawing replaced former drawings YT-1-1 though YT-111. At that meeting, the Chairman, ASESB, also read into the record that Stradley (Yurt) magazines which are constructed in accordance with Standard OCE Drawings 33-15-58 and/or 33-15-61 are considered to be equivalent in strength to the OCE's standard earth covered igloo magazines. Two door sizes are shown on the drawing: a 10' X 10' door and a 12'X 12' door- DDESB memo of 22 Apr 1980 discusses the successful testing of the two-leaf sliding door of 33-15-61 as pan of ESKIMO II. |

||||||||||||||||||

| RC Stradley | 33-15-61-6 | Similar to 33-15-61 | ||||||||||||||||

Reference Information - RC Stradley

Comments/Design ConsiderationVery similar to 33-15-61, which is a 7-Bar ECM. Only differences were the use of a 10' door and 3,000 psi concrete vice a 12' door and 2,500 psi concrete. Doors and headwall were analyzed and were found to meet 7-Bar criteria. COE Huntsville e-mail of 24 January 2003 to DDESB documents results of review and analysis. |

||||||||||||||||||

| N/A | 33-15-62 | Applies to 33-15-01, 33-15-06 ad 652-686 through 652-692 | ||||||||||||||||

Reference Information - N/A

Digital DrawingsComments/Design ConsiderationThis is not an ECM design drawing. This drawing permitted installation of larger doors on specific magazines, on the basis that the strength of the modified structures remained unchanged as a result of the door modifications. This drawing applied to ECM 33-15-01, 33-15-06 and 652-686 - 652-692. |

||||||||||||||||||

| Steel, Semi-Circular Arch | AW33-15-63 | |||||||||||||||||

Reference Information - Steel, Semi-Circular Arch

Comments/Design ConsiderationApproved during 225th ASESB meeting of 19 Feb 64 as a standard magazine design. A 1 Apr 87 COEHQ letter stated that ECM design AW 33-15-63 was no longer being used for new construction. Drawing AW 33-15-63 had two designs shown on it. One is a traditional magazine with a single 12-inch thick reinforced concrete headwall, while the second is a design with two headwalls and doors (flow through design) COE structural evaluation of AW 33-15-63 door in 2003 determined the door would not provide 7 or 3- Bar protection. The conversion of these designs from Standard magazines to 7-Bar magazines in the early 1990s was in error in that the hinged doors of AW 33-15-63, AW 33-15-64 and 33-15-65 (all similar door designs) are not capable of providing 7 or 3-Bar protection to their contents. This determination was arrived at during ESKIMO III, which tested a AW 33-5-64 design and by a structural analysis of the door design that was conducted by the Huntsville COE at the request of DDESB-KT. Paragraph C2.3.7.3. ESKIMO III, June 1974 provides further information regarding this test. If different doors than those shown of AW 33-15-63, AW 33-15-64, and 33-15-65 have been installed, then the headwall and alternate door(s) can be structurally evaluated to determine their strength. As a result of the ESKIMO series tests, services began moving towards single and bi-sliding doors or hardened headwall pilasters and header. Siting guidance: Do not use for new construction. Site existing magazines as Undefined structures to provide a higher level of protection to contents. Use of the K4.5 that is permitted for 7-Bar ECM (face-to-face) with intervening barricades or the K6 permitted for 7-Bar ECM (face-to-face) without a barricade provides a very high likelihood of prompt propagation between ECM designed to AW 33-15-63, AW 33-15-64 and 33-15-65. |

||||||||||||||||||

| Steel Arch | AW33-15-64 | |||||||||||||||||

Reference Information - Steel Arch